Established in 2000, Hubei Cremo Abrasive Co., Ltd. has built a solid reputation for excellence in the industry. With years of experience and a commitment to innovation, the company has consistently delivered top-notch metal tin can and tea tin container products to its customers. Situated in Guangzhou, China, the company benefits from a strategic location that provides efficient transportation by water, land, and air, facilitating seamless operations and timely delivery of orders.

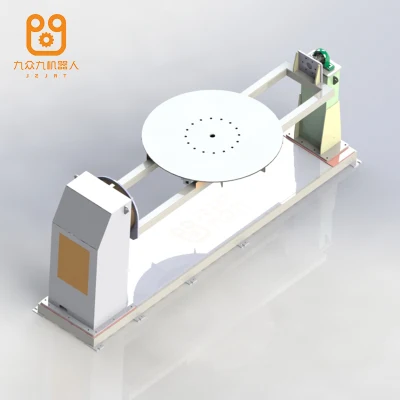

The 6m x 6m column and boom welding manipulator represents a significant investment for Hubei Cremo Abrasive Co., Ltd., reflecting the company's dedication to staying at the forefront of technological advancements in manufacturing. This cutting-edge equipment offers a wide range of benefits, including enhanced precision, increased speed, and the ability to handle larger workpieces with ease. With the implementation of this welding manipulator, the company is poised to elevate the quality and efficiency of its production processes, ultimately leading to improved products for its customers.

The welding manipulator is a versatile and multifunctional piece of equipment that is designed to streamline the welding process. It features a column-mounted boom that can be maneuvered in multiple directions, providing access to a wide area for welding operations. This allows for greater flexibility and efficiency in handling various sizes and types of products, making it an invaluable asset for a company like Hubei Cremo Abrasive Co., Ltd. that specializes in the production of metal tin cans and tea tin containers.

One of the key advantages of the 6m x 6m column and boom welding manipulator is its ability to automate and precisely control the welding process. This results in higher quality welds, improved consistency, and reduced material waste, ultimately leading to cost savings and a more sustainable production process. With the integration of this advanced technology, Hubei Cremo Abrasive Co., Ltd. is expected to enhance its manufacturing capabilities, allowing for increased output and faster lead times for its products.

Furthermore, the implementation of the welding manipulator underscores the company's commitment to maintaining the highest standards of quality in its production processes. By investing in cutting-edge technology, Hubei Cremo Abrasive Co., Ltd. is demonstrating its dedication to delivering superior products that meet and exceed the expectations of its customers. The welding manipulator will enable the company to uphold its reputation for excellence and continue to set the benchmark for quality and innovation in the industry.

As Hubei Cremo Abrasive Co., Ltd. continues to expand and evolve, the integration of the 6m x 6m column and boom welding manipulator represents a significant milestone in the company's journey. With its advanced capabilities and potential for enhancing efficiency and quality, this state-of-the-art equipment is destined to play a pivotal role in driving the company's success and solidifying its position as a leader in the manufacturing of metal tin cans and tea tin containers. Customers can look forward to reaping the benefits of these advancements, as Hubei Cremo Abrasive Co., Ltd. remains dedicated to delivering top-notch products that consistently exceed expectations.