Basic Info.

Model NO.

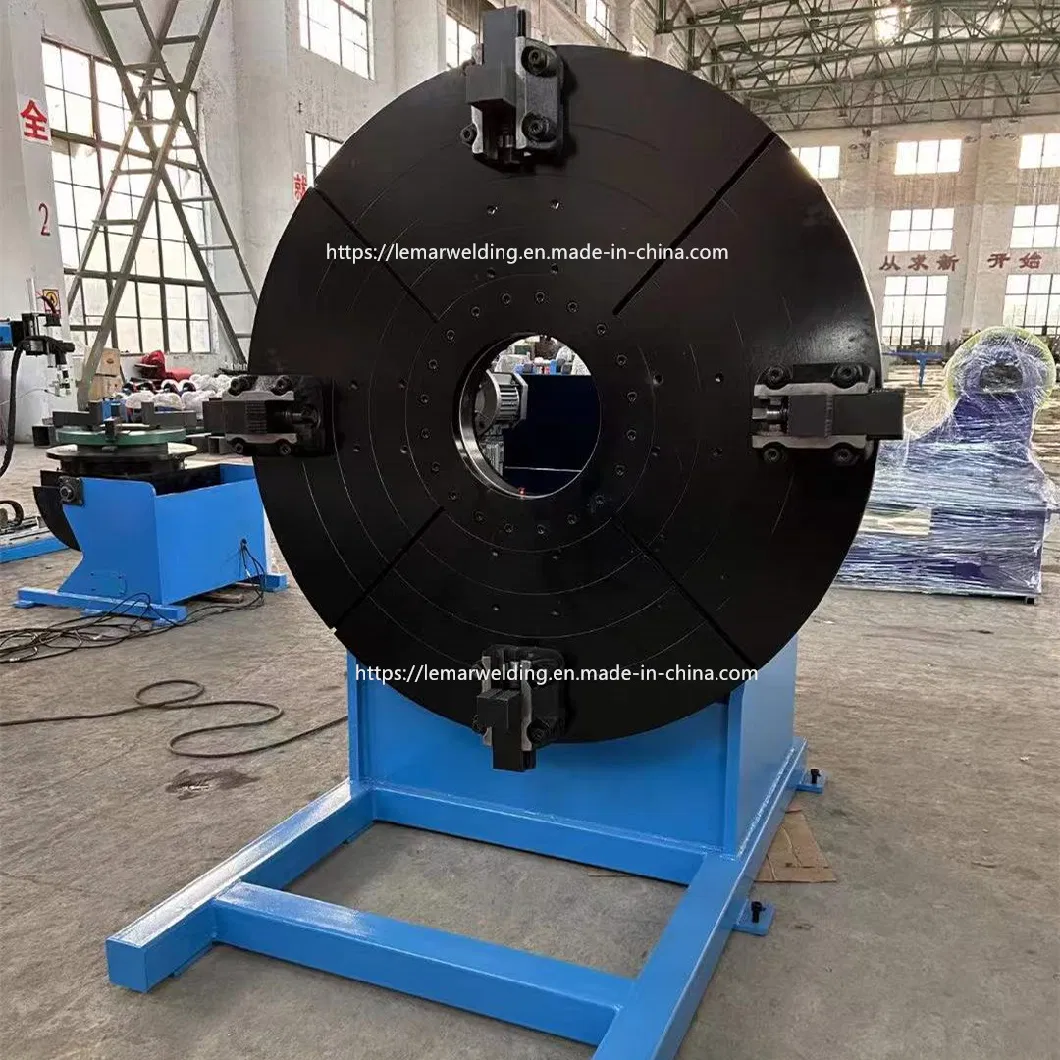

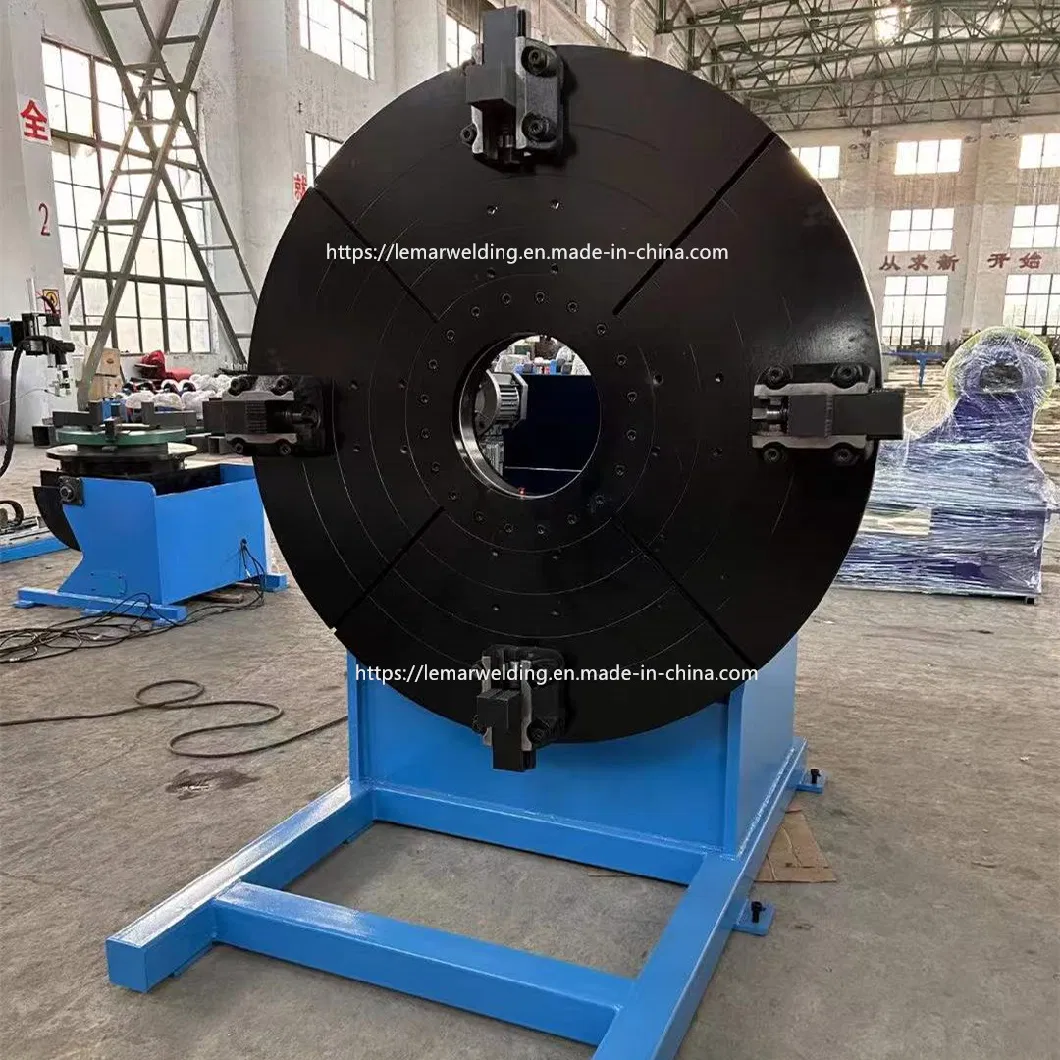

BWJ-12

Max Eccentricity Distance

250mm

Tilting Angle

0-135°

Voltage

110V/220V

Condition

New

Model

Bwj-12

Max Loading Weight

1200kg Welding Positioner

Turntable Diameter

1400mm

Rotating Speed

0.02-0.2rpm

Speed Control

VFD Control

Overturning Speed

0.1rpm

Rotating Motor Power

1.1kw

Overturning Motor Power

2*1.1kw

Worktable Welding Chuck

3 Jaw Welding Chuck

Lead Time

10 Days

Work for

Tank Seam Welding Turning Table

Colour

Customized

Work with

Welding Manipulator

CNC

Customized

Warranty

13 Months

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

3000PCS/Year

Packaging & Delivery

Package Size

170.00cm * 160.00cm * 75.00cm

Package Gross Weight

650.000kg

Product Description

1200kg Auto Welding positioner Pipe Flange welding Girth Turntable

Welding positioners play a crucial role in the welding industry, allowing workers to achieve optimal welding angles and positions. These machines come in a variety of shapes and sizes, each with unique capabilities and features.

How many kinds of welding positioner?

There are various types of welding positioners available in the market.

Each of these positioners has its unique features and capabilities to cater to different welding requirements.

Some of the common welding positioners include tilt turning positioners, rotary positioners, and robotic welding headstock positioners.

Tilt and turning positioners are ideal for welding pipes and tubes, while rotary positioners are suitable for welding cylindrical objects. Headstock positioners, on the other hand, are perfect for welding heavy and bulky materials. Understanding the different types of welding positioners can help you choose the right equipment for your welding project. Invest in high-quality positioners to ensure efficient and precise welding results.

Specifications:

Specifications:

Welding positioners play a crucial role in the welding industry, allowing workers to achieve optimal welding angles and positions. These machines come in a variety of shapes and sizes, each with unique capabilities and features.

How many kinds of welding positioner?

There are various types of welding positioners available in the market.

Each of these positioners has its unique features and capabilities to cater to different welding requirements.

Some of the common welding positioners include tilt turning positioners, rotary positioners, and robotic welding headstock positioners.

Tilt and turning positioners are ideal for welding pipes and tubes, while rotary positioners are suitable for welding cylindrical objects. Headstock positioners, on the other hand, are perfect for welding heavy and bulky materials. Understanding the different types of welding positioners can help you choose the right equipment for your welding project. Invest in high-quality positioners to ensure efficient and precise welding results.

| Model | Weight Bearing(kg) | Overturning Velocity(rpm) | Speed of Turning Table(rpm) | Turning Angle(°) | Size of Working Table(mm) | Turning(kw) | Overturning(kw) | Setting Method | Max Turning Diameter(mm) |

| BWJ-01 | 100 | 0.1-1 | Manual | 0-120 | ¢400 | 0.18 | / | Frequency Conversion Stepless Speed | ¢600 |

| BWJ-03 | 300 | 0.2-2 | Manual | 0-90 | ¢600 | 0.18 | / | ¢800 | |

| BWJ-06 | 600 | 0.09-0.9 | 1.1 | 0-90 | ¢1000 | 0.75 | 0.75 | ¢1500 | |

| BWJ-12 | 1400 | 0.05-0.5 | 0.67 | 0-90 | ¢1200 | 1.1 | 1.1 | ¢2050 | |

| BWJ-30 | 3000 | 0.05-0.5 | 0.23 | 0-120 | ¢1400 | 1.5 | 1.5 | ¢2100 | |

| BWJ-50 | 5000 | 0.05-0.5 | 0.14 | 0-120 | ¢1500 | 2.2 | 3 | ¢2500 | |

| BWJ-100 | 10000 | 0.05-0.5 | 0.14 | 0-120 | ¢2000 | 3 | 5.5 | ¢3200 |