Basic Info.

Model NO.

BWJ-1200

Max Eccentricity Distance

150mm

Tilting Angle

0-90°

Voltage

110V/220V

Condition

New

Function

Pipe Flange Welding Turning Table

Control Mode

Normal or CNC

Horizontal Loading Weight

1200kg

Vertical Loading Weight

1200kg

Rotation Speed

0.1-1.0rpm

Tilting Motor

1.1kw

Worktable Diameter

1200mm

Rotation Motor

0.75kw

Suitable Chuck

300/400/500mm Welding Chuck

Colour

Customized

Lead Time

5 Days

Pedal Switch

Yes

Optional

TIG MIG Mag Welding Machine

Postioner Type

Seat Type

OEM

Yes

Transport Package

Standard Package

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

30000PCS/Year

Packaging & Delivery

Package Size

430.00cm * 240.00cm * 230.00cm

Package Gross Weight

780.000kg

Product Description

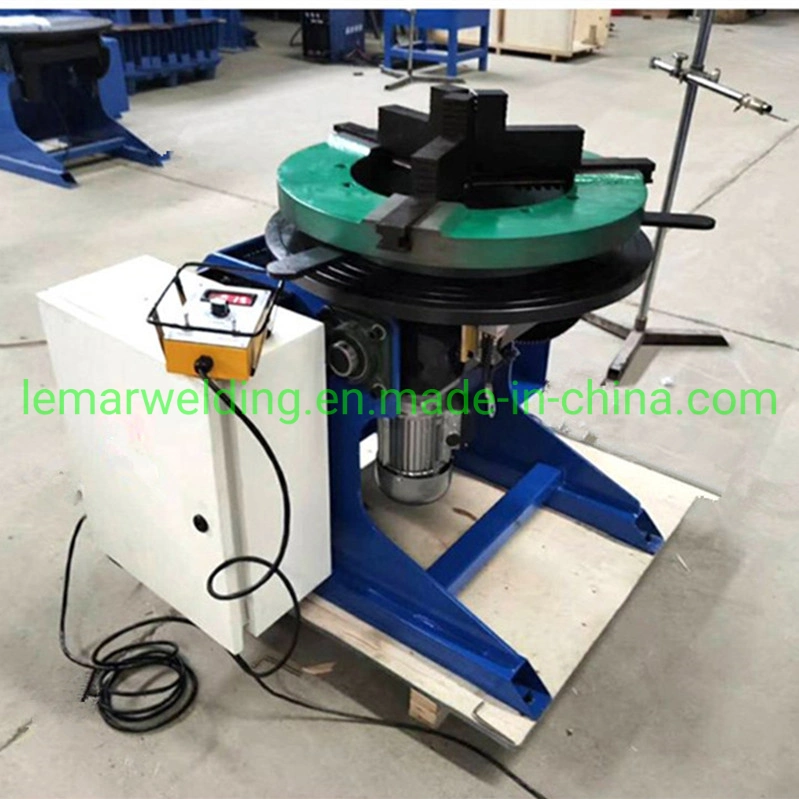

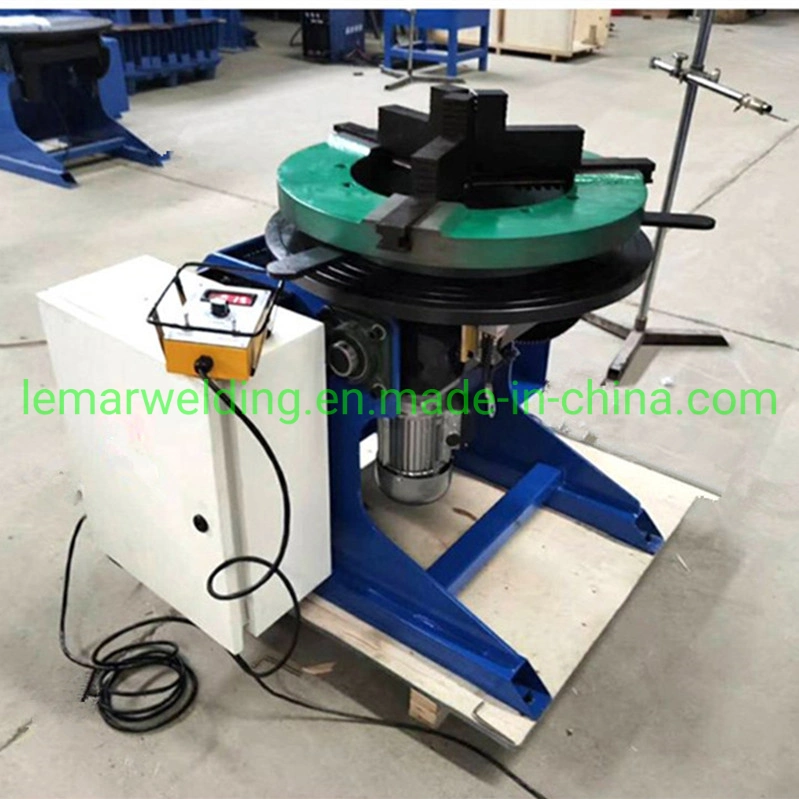

1200kg Vertical Load Capacity welding positioner 120 degree Tilt Angle tables

The welding positioner is generally composed of a worktable rotary mechanism and a turning mechanism.

Through the lifting, turning and turning of the worktable, the workpiece fixed on the worktable can reach the required welding and assembly angle. , a satisfactory welding speed can be obtained.

Positioners increase productivity by removing unnecessary time from various processes.

Welding positioners guarantee the longest possible arc time.

The welder can swiftly modify the workpiece when automatic 360°positioners turning tables are used!

Positioners make it possible for one operator to accomplish the task of repositioning massive pieces, eliminating the need for many workers. This results in labor savings and frees up workers to complete other tasks.

Specifications:

Specifications:

Wuxi Lemar's Product range of welding auxiliary equipment:

10kg/30kg/50kg/100kg/200kg/300kg~15T CE certified light welding positioner and heavy duty welding positioner;

Flange/pipe automatic welding machine;

Heavy-duty positioner with large through hole;

Pressure roller positioner/roller rotator;

Self-adjusting/adjustable welding roller rotator;

Carbon steel/stainless steel/aluminum alloy and other circular workpiece straight seam welding machine;

PLC control stainless steel ring seam automatic welding machine;

Carbon steel/stainless steel/copper/aluminum and other MIG TIG SAW welding machines;

Welding Chuck/Gun Holder/Pneumatic Tailstock/Support Rack.

The welding positioner is generally composed of a worktable rotary mechanism and a turning mechanism.

Through the lifting, turning and turning of the worktable, the workpiece fixed on the worktable can reach the required welding and assembly angle. , a satisfactory welding speed can be obtained.

Positioners increase productivity by removing unnecessary time from various processes.

Welding positioners guarantee the longest possible arc time.

The welder can swiftly modify the workpiece when automatic 360°positioners turning tables are used!

Positioners make it possible for one operator to accomplish the task of repositioning massive pieces, eliminating the need for many workers. This results in labor savings and frees up workers to complete other tasks.

| Model | Max loading Kg | Worktable diameter mm | Table rotation speed r/min | Table turning speed r/min | Allowable center of gravity X mm | Allowable eccentricity Y mm | Rotary motor(kw) | Flip motor (kw) | Table height mm |

| BWJ-12 | 1200 | 1200 | 0.1-1 | 0.1-1 | 200 | 250 | 1.1kw | 0.75kw | Customized |

10kg/30kg/50kg/100kg/200kg/300kg~15T CE certified light welding positioner and heavy duty welding positioner;

Flange/pipe automatic welding machine;

Heavy-duty positioner with large through hole;

Pressure roller positioner/roller rotator;

Self-adjusting/adjustable welding roller rotator;

Carbon steel/stainless steel/aluminum alloy and other circular workpiece straight seam welding machine;

PLC control stainless steel ring seam automatic welding machine;

Carbon steel/stainless steel/copper/aluminum and other MIG TIG SAW welding machines;

Welding Chuck/Gun Holder/Pneumatic Tailstock/Support Rack.