- Overview

- Product Description

- Product Parameters

- Product classification

Basic Info.

Model NO.

ZTG-1

Model

Ztg-1

Max Loading Weight

1 Ton

Function

Tank Vessesl Automatic Welding Turning Rolls

Usage

Welding and Cutting Turning

Exported to

Canada,USA,Russia,Saudi Arabia,Iraq,Greece,France

Tanks Diameter

500-3000mm

Wheel Diameter

Polyurethane(PU)/Steel Metal

Roller Linear Speed

6-60m/H

Motor Power

120W

Speed Mode

AC Variable Frequency Stepless Speed Regulation

Certificate

CE ISO

Brand

Lemar

Warranty

1 Year

Wheels Quantity

4 Wheels

Speed Adjust Way

VFD Adjustment

Transport Package

Wooden Box

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

10000 PCS/Year

Packaging & Delivery

Package Size

55.00cm * 59.00cm * 65.00cm

Package Gross Weight

90.000kg

Product Description

1T Self Adjustable Tank Welding Rotators for long pipes rotate

1000kg welding rotator is an incredibly powerful piece of equipment that has the ability to revolutionize the welding process.This rotator can easily handle and spin large, heavy welding pipes tanks and other vessel because to its remarkable carrying capacity.

The capacity of a welder rotator to increase productivity and efficiency in circular seam or straight seam welding projects is one of its most important advantages.

The pipe tank or vessel can be continuously rotated by the rotator, which speeds up and improves the efficiency of welding.

Additionally, self aligning turning roll has the ability to rotate the workpiece at a precise angle, guaranteeing even welding and lowering the chance of mistakes.

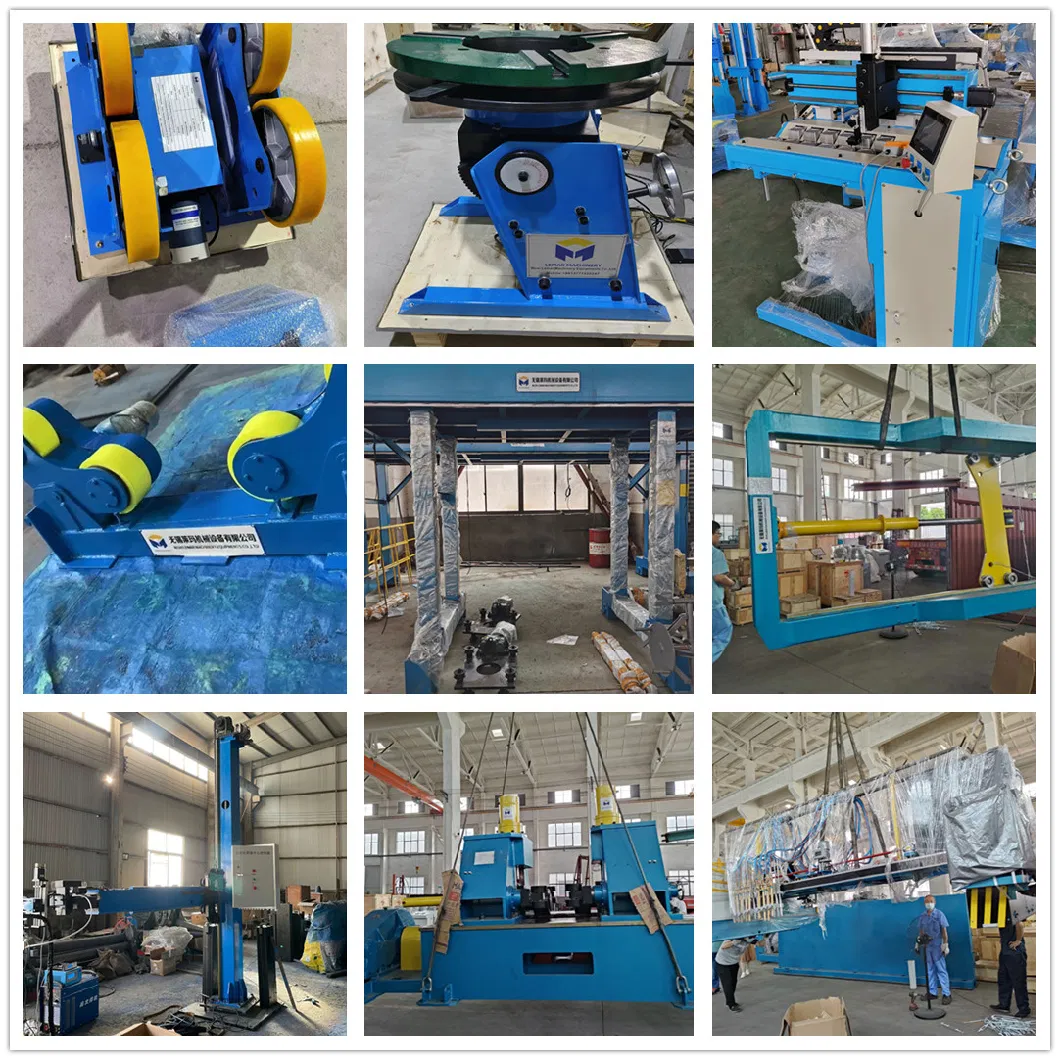

Wuxi Lemar Machinery Equipment Co., Ltd. is an enterprise specializing in the design and manufacture of complete sets of automatic welding and cutting equipment.

The products are diversified and highly compatible, and are widely used in boilers, pressure vessels, metallurgical construction, equipment installation, power plant construction, shipbuilding and other industries.

The main products include CNC Plasma Flame cutting machine, Welding rotator, Welding manipulator column and boom type, Welding turning turntable positioner, and other automatic welding and cutting equipment.

Model

| Loading Capacity (kg) | Pipe/Tank Diameter (mm) | Rubber Roller Dia. & Width (mm) | Roller Speed (m/h) | Motor Power (kw) |

Speed Adjust

| |

Rubber Roller | Steel Roller | ||||||

| ZTG-1 | 1000 | 20-800 | Φ250*50 | 6-60 | 0.12 | Variable Frequency Drive (VFD)

| |

| ZTG-3 | 3000 | 50-1000 | Φ250*50 | 0.12 | |||

ZTG-5 | 5000 | Φ250-2300 | Φ250*100 | Φ240*20*2 | 0.75 | ||

ZTG-10 | 10000 | Φ320-2800 | Φ300*120 | Φ290*25*2 | 1.1 | ||

ZTG-20 | 20000 | Φ500-3500 | Φ350*120 | Φ340*30*2 | 1.5 | ||

ZTG-30 | 30000 | Φ600-3800 | Φ350*120 | Φ340*30*2 | 2.2 | ||

ZTG-40 | 40000 | Φ600-4200 | Φ400*120 | Φ390*40*2 | 3 | ||

ZTG-50 | 50000 | Φ700-4500 | Φ400*120 | Φ390*40*2 | 4 | ||

ZTG-60 | 60000 | Φ750-4800 | Φ450*120 | Φ440*50*2 | 4 | ||

ZTG-80 | 80000 | Φ850-5000 | Φ500*120 | Φ490*60*2 | 5.5 | ||

ZTG-100 | 100000 | Φ1000-5500 | Φ500*120 | Φ490*70*2 | 7.5 | ||

ZTG-150 | 150000 | Φ1100-6000 | Φ500*120 | Φ600*Φ280 | 2*5.5 | ||

| ZTG-250 | 250000 | Φ1200-7000 | / | Φ700*380 | 2*5.5 | ||

| ZTG-500 | 500000 | Φ1800-8000 | / | Φ850*350 | 2*7.5 | ||

| Type | Features | Suitable for using |

| Steel turning rolls | Strong carrying capacity, easy to manufacture | Heavy-duty weldments ≥ 60T, and weldments that require preheating |

| Polyurethane rubber wheel roller frame | The steel wheel rotator is covered with rubber wheels, which has high friction and smooth transmission, but the rubber is easy to be crushed | ≤10T weldments and non-ferrous metal cans and other containers |

| Steel and rubber combination wheels | The combination of steel wheels and rubber wheels, welding turning wheels rotator has a higher load-carrying capacity than ordinary rubber wheels, and the transmission is stable | 10-60T jars, tanks and weldments |

| Track wheel rotator | The large area of the track and the weldment is in contact with the weldment, which is beneficial to prevent the deformation of the thin-walled workpiece, and the transmission is stable but the structure is relatively complicated | For light, thin-walled and large-diameter weldments and non-ferrous metal containers |

A 1000 kg welding rotator also provides flexibility in the welding operation. It has a variety of uses, such as pipeline welding, shipbuilding, bridge building, and other things. It is an invaluable tool for any welding endeavor because of its versatility.

FAQ:

1.Who are we?

Wuxi Lemar is one professional supplier of CNC Plasma Flame Gas cutting products and Automated welding equipment

2.How can we ensure quality?

Prior to mass manufacturing, there is always a pre-production sample; prior to shipment, there is always 100% quality inspection;

3. What products do we sell?

H beam production line machines,Box beam production line machine,CNC Plasma Flame cutting machines,Welding rotators,Welding turntable positioner,Welding manipulators,Seam welding machines,Welding torch, gas regulator, and accessories

4. What makes us better than other providers for your purchases?

15 years of welding industry experience.

Expert staff for quality assurance and technology R&D.

Quick, responsible, and top-notch service

5. What services are available from us?

FOB, CFR, CIF, EXW, DDU, and express delivery are acceptable terms for delivery;

6.Accepted Currencies for Payment: USD, EUR, and CNY;

Accepted forms of payment include cash, Western Union, credit card, T/T, and L/C.