Basic Info.

Model NO.

BWJ-20

Condition

New

Function

Pipe Flange Welding Turning Table

Control Mode

Normal or CNC

Horizontal Loading Weight

2000kg

Vertical Loading Weight

1000kg

Rotation Speed

0.05-0.5rpm

Tilting Motor

1.1kw

Worktable Diameter

130mm

Rotation Motor

1.1kw

Speed Mode

AC Frequency

Colour

Customized

Exported to

USA,UK,Canada,Greece,Poland,Brazil,South Africa

Lead Time

5 Days

Pedal Switch

Yes

Optional

TIG MIG Mag Welding Machine

Postioner Type

Seat Type

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

3000PCS/Year

Product Description

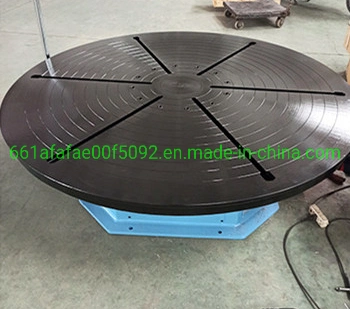

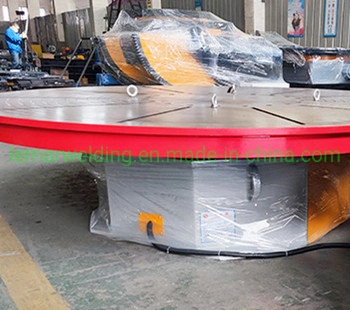

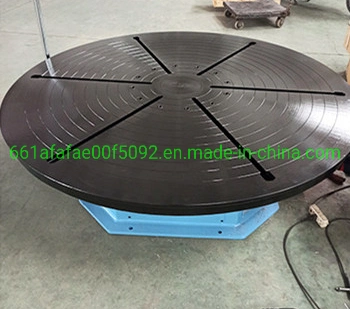

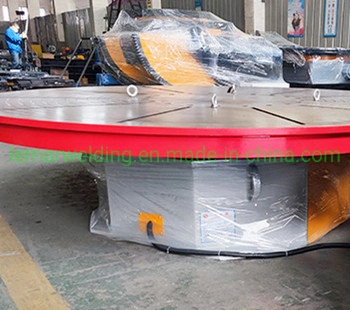

20 Ton Rotary Welding Positioner 1300mm Diameter welding Turntable

The worktable of the seat type welding positioner can be turned over freely at 0-135 degrees, and the workpieces such as the pipe, flange, tank and other workpieces can be turned over to the ideal welding position for welding during operation.

The welding positioner is mainly used for the welding of some pipes and plates, and it is easy to move.

Welding tilting turntable is the most widely used structural form at present, and it is often used in conjunction with the column and boom welding manipulator.

Specifications:

Specifications:

Features of Automatic Welding positioner:

1. Slewing drive: The slewing drive of automatic pipe flange welding positioner should realize stepless speed regulation and be reversible.

2 Within the rotation speed range, the rotation speed should not fluctuate by more than 5% when receiving the maximum load.

3. Inclined drive: The inclined drive should be stable, without shaking under the maximum load, and the whole machine should not overturn. The maximum load Q exceeds 25kg, and it should have a power drive function.

4 There should be a limit device to control the angle of inclination, and an angle indicator.

The worktable of the seat type welding positioner can be turned over freely at 0-135 degrees, and the workpieces such as the pipe, flange, tank and other workpieces can be turned over to the ideal welding position for welding during operation.

The welding positioner is mainly used for the welding of some pipes and plates, and it is easy to move.

Welding tilting turntable is the most widely used structural form at present, and it is often used in conjunction with the column and boom welding manipulator.

| Model | Max loading Kg | Worktable diameter mm | Table rotation speed r/min | Table turning speed r/min | Allowable center of gravity X mm | Allowable eccentricity Y mm | Rotary motor(kw) | Flip motor (kw) | Table height mm |

| BWJ-20 | 2000 | 1200-1400 | 0.05-0.5 | 0.4r/min | 200 | 250 | 1.1 | 1.5 | Customized |

1. Slewing drive: The slewing drive of automatic pipe flange welding positioner should realize stepless speed regulation and be reversible.

2 Within the rotation speed range, the rotation speed should not fluctuate by more than 5% when receiving the maximum load.

3. Inclined drive: The inclined drive should be stable, without shaking under the maximum load, and the whole machine should not overturn. The maximum load Q exceeds 25kg, and it should have a power drive function.

4 There should be a limit device to control the angle of inclination, and an angle indicator.