Basic Info.

Model NO.

BWJ-03

Condition

New

Function

Pipe Flange Welding Turning Table

Control Mode

Normal or CNC

Max Loading Weight

300kg(Can Customized)

Table Turning Angle

0-135

Turning Table Rotation Speed

0.1-1 Rpm

Table Diameter

600mm

Motor

0.37kw

Flip Angle

0-90

Lead Time

3 Days

Chuck

Optional

Welding Mode

Pipe TIG MIG Welding

Warranty

1 Year

Color

Customized

CE Certificate

Yes

Customized

Yes

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

3000PCS/Year

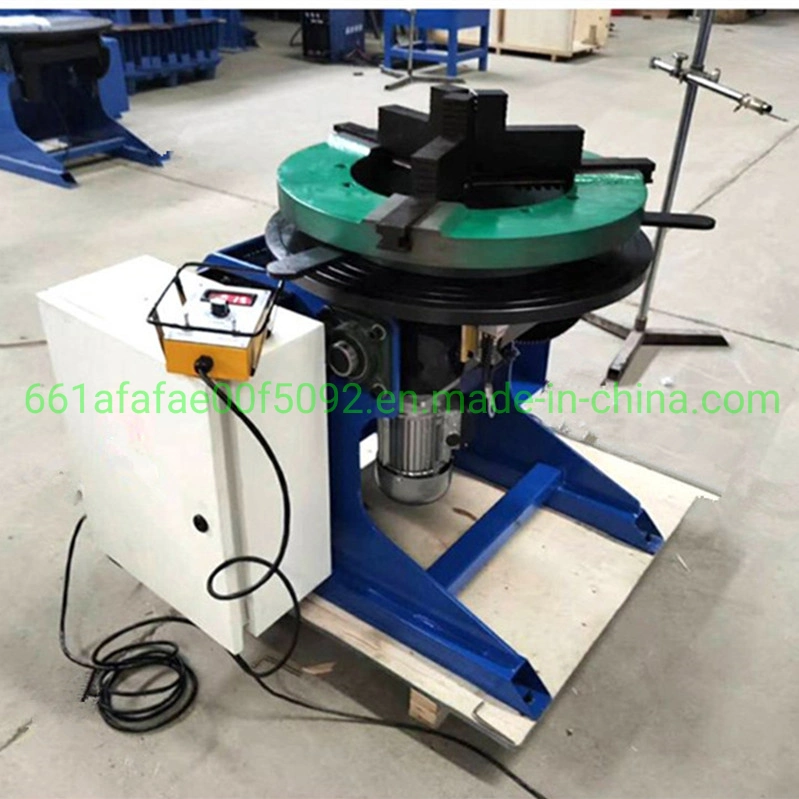

Product Description

300kg welding positioner is mainly used for the inversion, rotation and displacement of shafts, discs, circular and annular workpieces.

With a weight of less than 300kg and a diameter of 10-600mm, so as to obtain the ideal processing position and welding speed.

Application of welding positioner:

Manual welding or automatic welding

Cut

Spray

Precision automatic welding

With a weight of less than 300kg and a diameter of 10-600mm, so as to obtain the ideal processing position and welding speed.

Application of welding positioner:

Manual welding or automatic welding

Cut

Spray

Precision automatic welding

Specifications:

| Model | BWJ-03 | Input power | AC220V |

| Horizontal loading | 300KG | Vertical loading | 150KG |

| Work table diameter | 500mm | Work table height | 650mm |

| Rotate speed | 0.2-2.5rpm | Rotate motor | 300W |

| Flip angle | 0-90° | Flip mode | Manual/Electric |

| Oversize | 590L*650W*650H | Weight | 120kg |

| Suitable chuck | KP-300/400/500 | Warranty | 1 year |

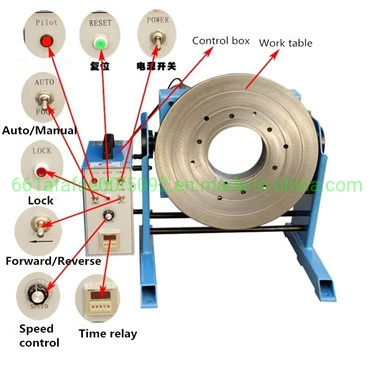

Standard configuration:

Mechanical part of Welding positioner

Control box

Foot switch

Power cable

Manual

Certificate

Optional accessories:

Welding chuck(KP-200/300/400/500)

Welding bracket

Adjustable Height Stand

Pneumatic tail top

Mechanical part of Welding positioner

Control box

Foot switch

Power cable

Manual

Certificate

Optional accessories:

Welding chuck(KP-200/300/400/500)

Welding bracket

Adjustable Height Stand

Pneumatic tail top

About the welding chuck:

The welding positioner is generally equipped with a three-jaw welding chuck, and there are also specially customized heavy-duty welding chucks.

Welding chuck of automatic welding positioner is generally composed of three parts: the chuck body, the movable jaw and the jaw drive mechanism.

It is a machine tool accessory that clamps and positions round workpieces (pipes, flanges, etc.) by using the radial movement of movable jaws evenly distributed on the chuck body. chuck.

The minimum diameter of the chuck body is 65 mm and the maximum is 1500 mm, and there is a through hole in the center to pass the workpiece or bar; the back has a cylindrical or short conical structure, which is directly or through the flange to connect with the end of the machine tool spindle .

The welding positioner is generally equipped with a three-jaw welding chuck, and there are also specially customized heavy-duty welding chucks.

Welding chuck of automatic welding positioner is generally composed of three parts: the chuck body, the movable jaw and the jaw drive mechanism.

It is a machine tool accessory that clamps and positions round workpieces (pipes, flanges, etc.) by using the radial movement of movable jaws evenly distributed on the chuck body. chuck.

The minimum diameter of the chuck body is 65 mm and the maximum is 1500 mm, and there is a through hole in the center to pass the workpiece or bar; the back has a cylindrical or short conical structure, which is directly or through the flange to connect with the end of the machine tool spindle .

The matching chucks of our welding positioner are KP-200/300/400 and special KP-500 welding chucks.

The parameters are as follows:

| Chuck Model | Clampable range | Clamping range with extended jaws |

| KP-200 | 20-210mm | 5-300mm |

| KP-300 | 80-280mm | 10-400mm |

| KP-400 | 120-380mm | 10-500mm |

| KP-500 | 180-500mm | Max 600mm |