Basic Info.

Model NO.

BWJ-5T

Condition

New

Model No.

Bwj-5t

Max Load Capacity

5000kg

Table Speed

0.05~0.5rpm

Totating Motor

1.1kw

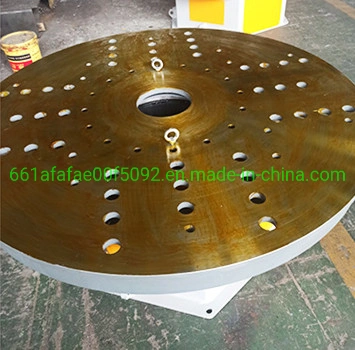

Turning Table Diameter

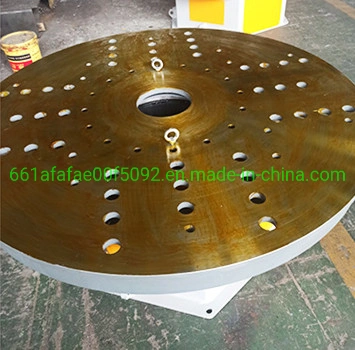

1600mm

Steel Plate Thickness

30mm

Customized

Yes

Lead Time

15 Days

Speed Adjustment

AC Frequency Converter Stepless Speed Adjustment

Welding for

Tank Pipe Flange Seam Welding Machine

Positioner Chuck

Optional

Tilt Motor Type

AC Motor

Positioner Type

Platform Fixed Welding Positioner

Turntable Heigh

520mm

Optional

Welding Manipulator,Welding Rotator

Transport Package

Standard

Trademark

Lemar

Origin

Jiangsu, China

HS Code

8428909090

Production Capacity

100PCS/Month

Product Description

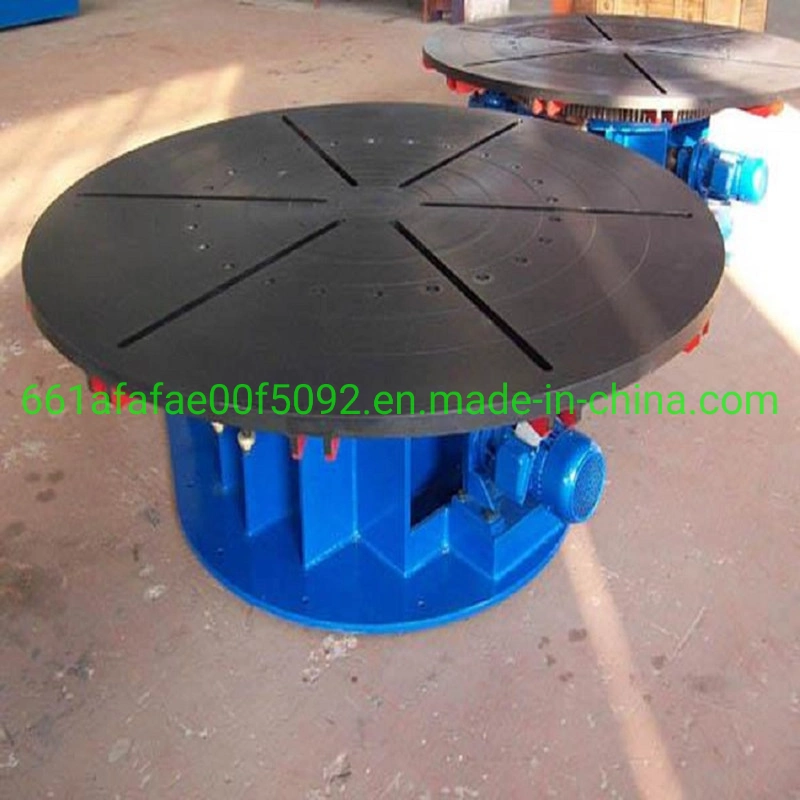

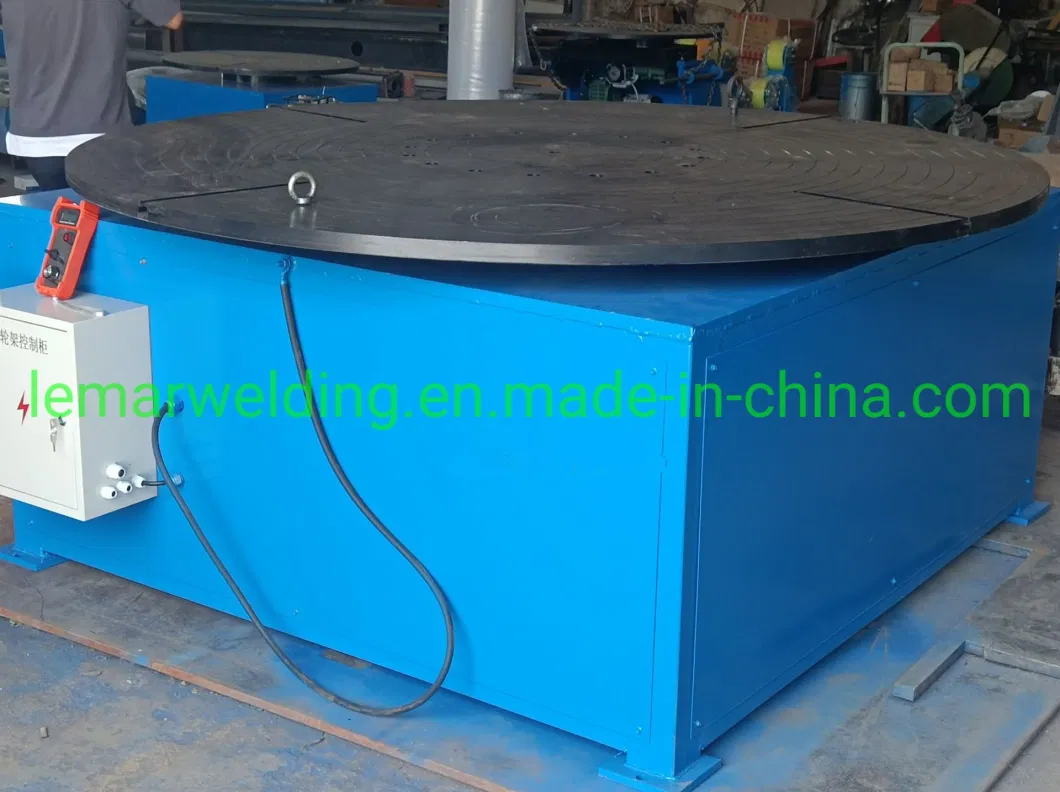

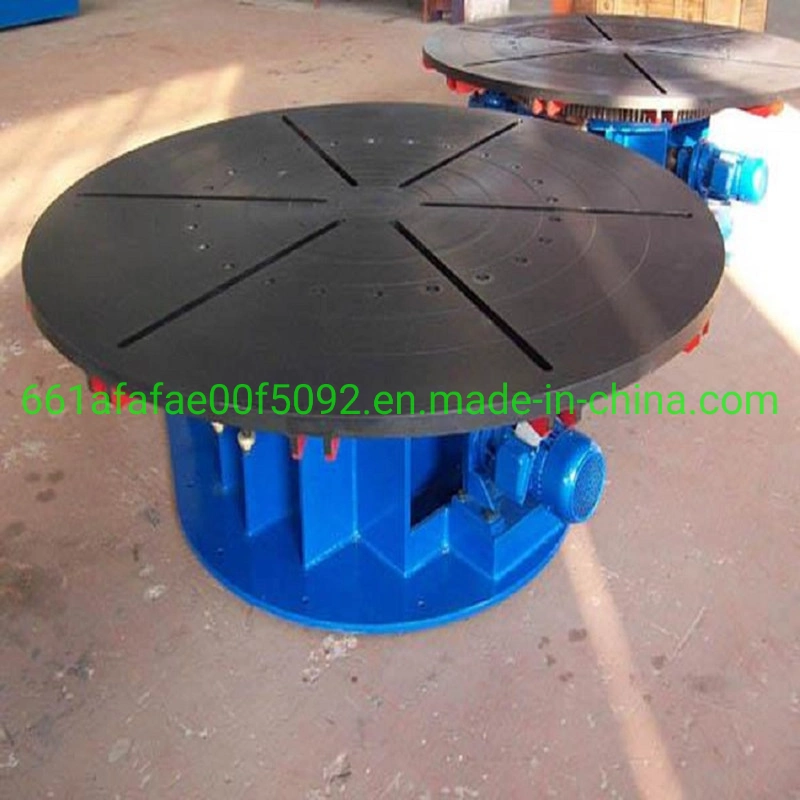

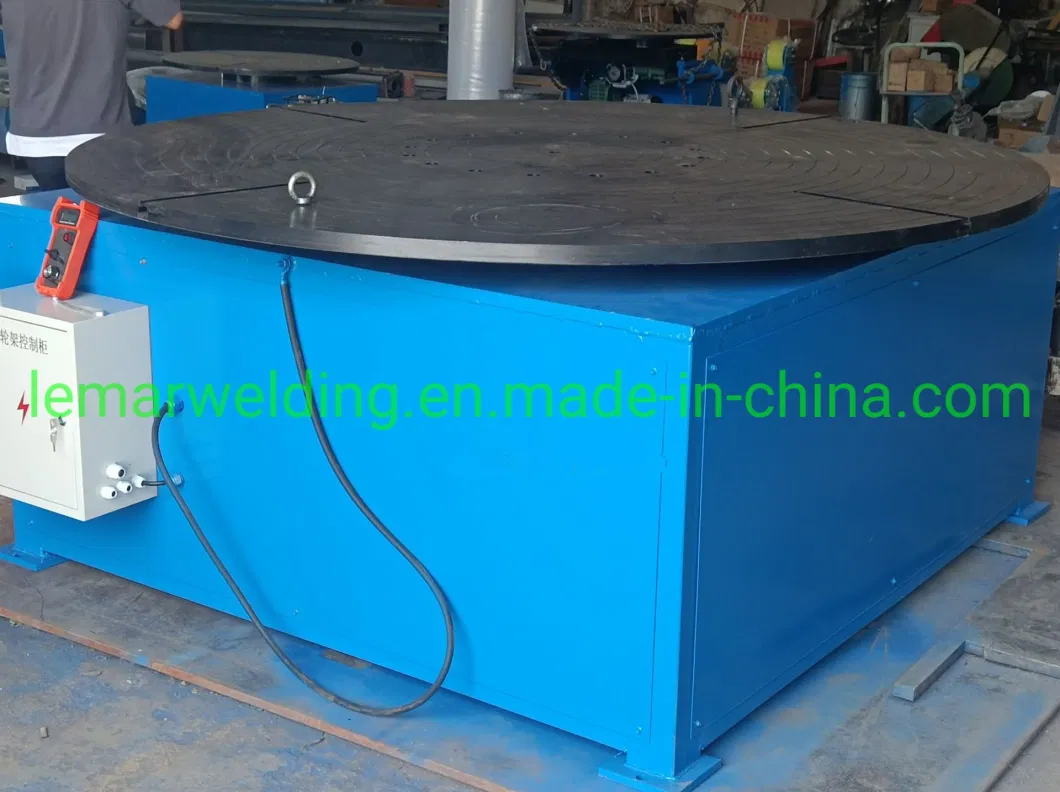

5T Tilt Welding Positioner Turntable Girth welding positioners

The welding turntable can be rotated in any direction within a 360-degree plane.

1.The control switch on the electrical box to control the positive and negative directions of the rotation, and use the foot switch to realize the start or stop of the rotation.

2. The turbine reducer of the automatic rotating pipe flange welding turntable is lubricated with lubricating oil, and the tilt adjustment mechanism and bearings are lubricated with grease, which ensures the service life of wearing parts such as gears.

3.Operation instruction of welding rotary table:

The electrode drives the belt, and the belt drives the first-stage turbine pair, which then drives the second-stage turbine pair, and finally drives the table top of the turntable to rotate 360 degrees without obstacles, which is convenient for welding, cutting and assembling of pipe flange tanks.

The speed regulation method of the welding rotary table adopts the AC frequency converter for speed regulation.

Specifications:

Specifications:

Notice:

1. We can also design various types of products according to customer needs;

2. Picture, price, product attributes are for reference only, and they are specific

You are welcome to place an order for an e -mail for consultation.

The welding turntable can be rotated in any direction within a 360-degree plane.

1.The control switch on the electrical box to control the positive and negative directions of the rotation, and use the foot switch to realize the start or stop of the rotation.

2. The turbine reducer of the automatic rotating pipe flange welding turntable is lubricated with lubricating oil, and the tilt adjustment mechanism and bearings are lubricated with grease, which ensures the service life of wearing parts such as gears.

3.Operation instruction of welding rotary table:

The electrode drives the belt, and the belt drives the first-stage turbine pair, which then drives the second-stage turbine pair, and finally drives the table top of the turntable to rotate 360 degrees without obstacles, which is convenient for welding, cutting and assembling of pipe flange tanks.

The speed regulation method of the welding rotary table adopts the AC frequency converter for speed regulation.

| Model | BWJ-1 | BWJ-2 | BWJ-3 | BWJ-5 | BWJ-10 | BWJ-20 | BWJ-30 |

| Loading weight | 1000kg | 2000kg | 3000kg | 5000kg | 10000kg | 20000kg | 30000kg |

| Turntable diameter | 1000mm | 1200mm | 1400mm | 1600mm | 1800mm | 2000mm | 2200mm |

| Turntable rotate speed | 0.1-1rpm | 0.1-1rpm | 0.1-1rpm | 0.05-0.5rpm | 0.05-0.5rpm | 0.04-0.4rpm | 0.04-0.4rpm |

| Rotate motor | 0.37kw | 0.55kw | 0.75kw | 1.1kw | 1.5kw | 3kw | 4kw |

| Eccentricity | 200mm | 250mm | 300mm | 300mm | 300mm | 300mm | 300mm |

| Turntable height | 415mm | 415mm | 515mm | 520mm | 600mm | 700mm | 750mm |

1. We can also design various types of products according to customer needs;

2. Picture, price, product attributes are for reference only, and they are specific

You are welcome to place an order for an e -mail for consultation.