Basic Info.

Model NO.

HGKZ500

Composed of

Hydraulic Fit up Rotator and Adjustable Rotator

Function

Pipe Tank Vessel Welding

Optional

Welding Manipulator

Fit up Mode

Hydraulic Welding Rotator

Rotator Moving

Manual or Electric

Max Hydraulic Rotator Loadint Weight

250 T or Customized

Max Electric Adjustable Welding Rotator

500 T or Customized

Lead Time

30 Days

Control

Wireless Remote Control 100m Length

VFD Brand Specifications

Famous Brand

Bearing

Zwz Bearing

Adjustable Rotator Quantity

Customized

Color

Customized

Walking Wheel Material

45# Steel Wheel Forgings

Outer Diameter of Roller

D 800mm

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Product Description

Adjustable Offshore Cylinder Automatic Moving Hydraulic lifting Welding Rotator

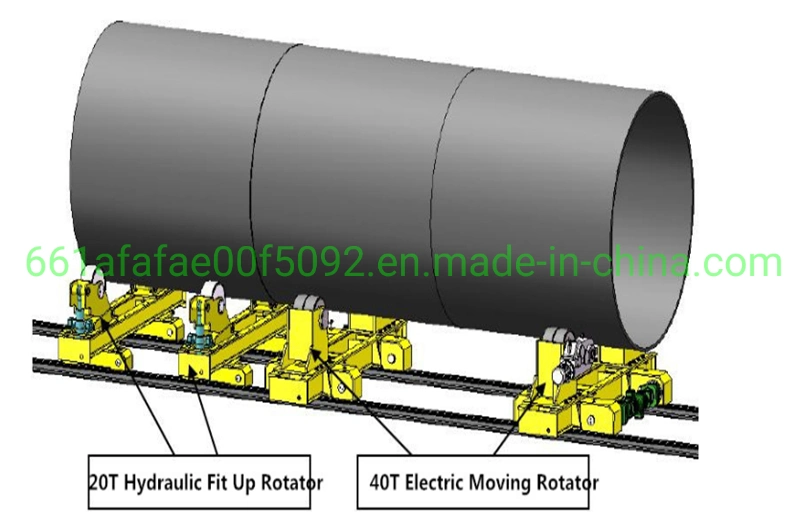

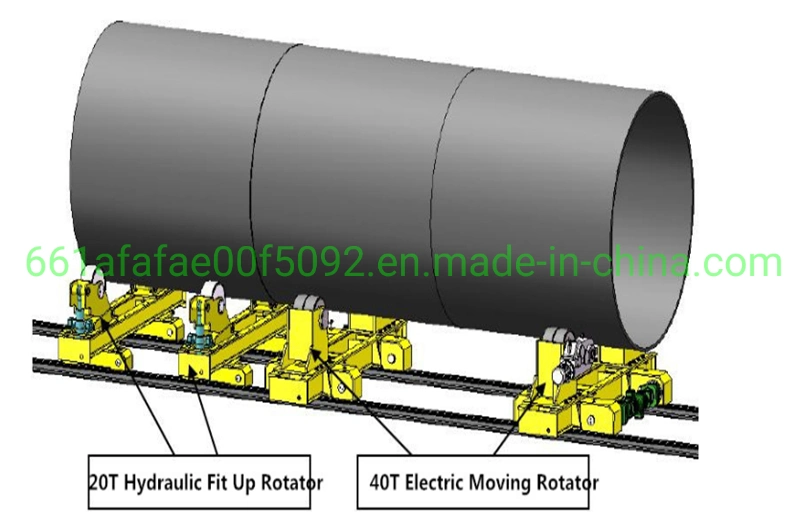

Fit up welding rotator is mainly used for face-to-face butt welding of two longer circular cylinders.

Depending on the size of the tank pipe cylinders, there are various grouping methods: light cylinder long axis type, hydraulic adjustable type, heavy cylinder hydraulic self-adjusting type, etc.

Hydraulic self adjustable moving type welding turning rolls are mainly used for long pipe fittings, among which heavy duty offshore wind tower tanks and thick steel plate cladding or narrow gap welded wind tower production are the most common.

The rotor has a large carrying capacity, and the two roller seats can be moved on the bed and fixed with high-strength bolts (grade 8.8) to adapt to tanks of different diameters.

Hydraulic roller rotator is mainly composed of:

Hydraulic welding rotator base

Driven roller assembly

Hydraulic cylinder

Hydraulic control system

Specification of 250T Hydraulic fit up welding turning rollers

Specification of 500T Electric moving adjustable welding rotator

Wuxi Lemar Machinery Equipments Co.,Ltd products:

Wuxi Lemar Machinery Equipments Co.,Ltd products:

CNC cutting equipment

H beam Box beam steel structure production lines

Complete sets of welding equipment.

Relying on advanced concepts, excellent technology, and exquisite craftsmanship, the company has formed a multi-variety and multi-series product structure.

Our products serve construction machinery, construction machinery, boilers and pressure vessels, steel structures, wind power and other industries, and the products are exported to Southeast Asia, the Middle East, Europe and the United States and many other countries.

Our company has passed ISO90001 quality system certification, ISO14001 environmental system certification

Fit up welding rotator is mainly used for face-to-face butt welding of two longer circular cylinders.

Depending on the size of the tank pipe cylinders, there are various grouping methods: light cylinder long axis type, hydraulic adjustable type, heavy cylinder hydraulic self-adjusting type, etc.

Hydraulic self adjustable moving type welding turning rolls are mainly used for long pipe fittings, among which heavy duty offshore wind tower tanks and thick steel plate cladding or narrow gap welded wind tower production are the most common.

The rotor has a large carrying capacity, and the two roller seats can be moved on the bed and fixed with high-strength bolts (grade 8.8) to adapt to tanks of different diameters.

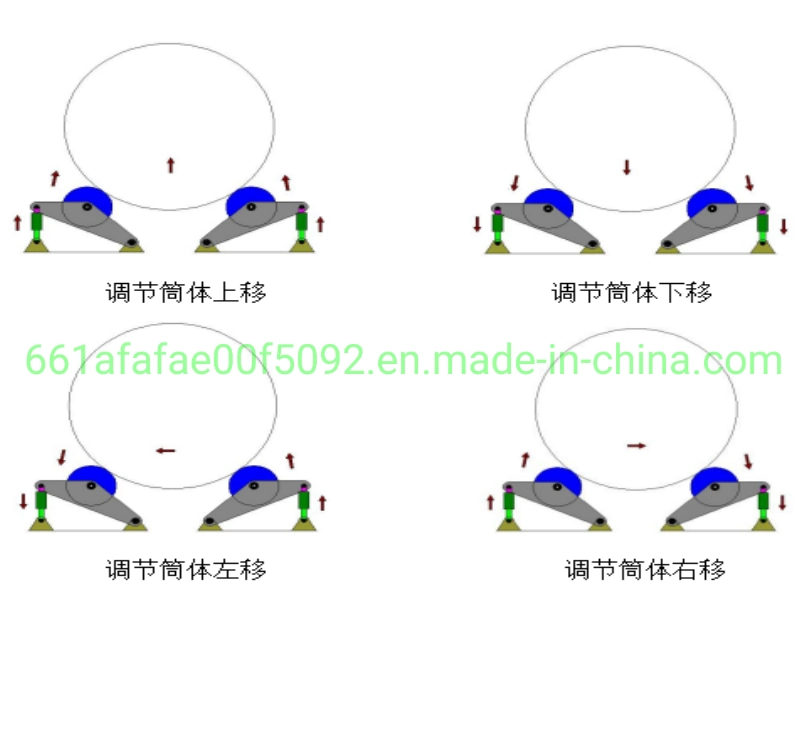

How dose the hydraulic ligting welding rotator work?

The hydraulic fit up roller turning rolls consists of a set of hydraulic jacking roller frames and a set of walking roller rotator.

Among them, the hydraulic lifting welding roller rotator is composed of two hydraulic cylinder rollers.

The walking roller frame can be matched with the active roller frame and the driven roller frame according to the length of the welding cylinder.

Four cylinders of the hydraulic jacking roller frame telescopically control the center distance of the four welding rollers, so that the tower sitting on it changes the height and the displacement in the horizontal direction, so as to completely fit the tower placed on the walking roller frame.

The rotation of the walking roller rotator is used to drive the rotation of the two towers, so that the tower group pair is completed synchronously, and the operation is completed on the automatic welding equipment, thereby completing the group pair welding of the entire tower body.

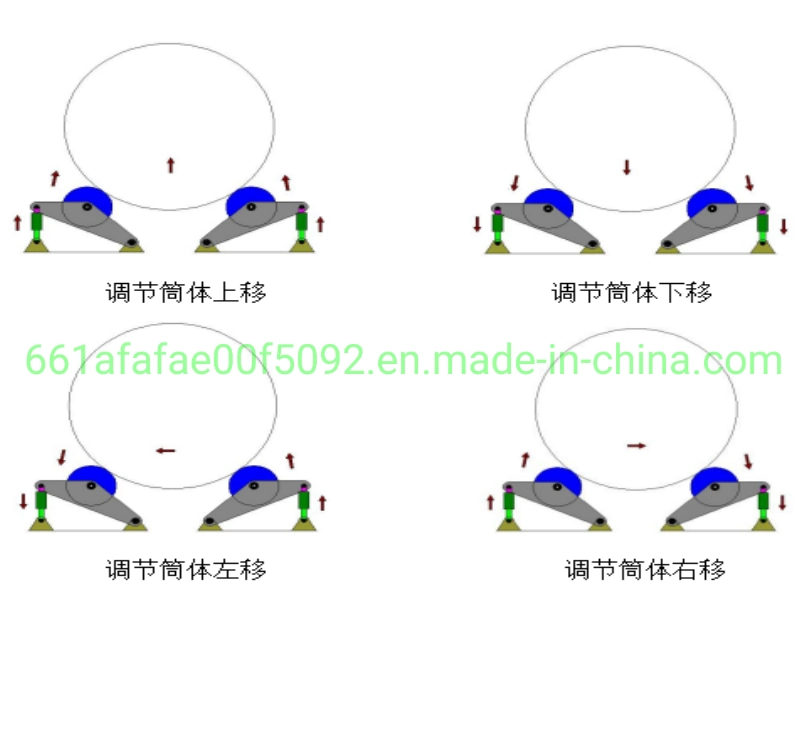

The hydraulic fit up roller turning rolls consists of a set of hydraulic jacking roller frames and a set of walking roller rotator.

Among them, the hydraulic lifting welding roller rotator is composed of two hydraulic cylinder rollers.

The walking roller frame can be matched with the active roller frame and the driven roller frame according to the length of the welding cylinder.

Four cylinders of the hydraulic jacking roller frame telescopically control the center distance of the four welding rollers, so that the tower sitting on it changes the height and the displacement in the horizontal direction, so as to completely fit the tower placed on the walking roller frame.

The rotation of the walking roller rotator is used to drive the rotation of the two towers, so that the tower group pair is completed synchronously, and the operation is completed on the automatic welding equipment, thereby completing the group pair welding of the entire tower body.

Hydraulic roller rotator is mainly composed of:

Hydraulic welding rotator base

Driven roller assembly

Hydraulic cylinder

Hydraulic control system

Specification of 250T Hydraulic fit up welding turning rollers

| No. | 250T Hydraulic fit up welding rotator(HGKZ250) | |

| 1 | Specification | 2 units driven type |

| 2 | Structure | Fixed |

| 3 | Loading weight | ≥250T |

| 4 | For tank range | Φ3000~φ8000mm |

| 5 | Roller material | 45#Steel forgings |

| 6 | Roller diameter | Φ700mm |

| 7 | Roller width | 300mm |

| 8 | Roller center distance adjustment method | Bolt hole step adjustment |

| 9 | Group-to-pair adjustment method | Hydraulic adjustment of roller center distance |

| 10 | Roller frame configuration hydraulic system | 1 station 4 cylinders |

| 11 | Group pair adjustment | Hydraulic cylinder up and down |

| 12 | Hydraulic cylinder stroke | 300mm |

| 13 | Working pressure of hydraulic station | 16Mpa |

| 14 | Hydraulic station motor power | 11kw |

| 15 | Control | Wireless remote control box |

| 16 | Gross weight | About 15 tons |

Specification of 500T Electric moving adjustable welding rotator

| 500T Adjustable welding rotator(Electric moving) 1 Drive and 2 Driven | ||

| Item | Specification | |

| ★ | Main components and functions of the equipment | 500T Adjustable welding rotator(electric moving) 1 Drive and 2 Driven Roller |

| ★ | Roller frame maximum load capacity | 500T |

| ★ | Adapt to workpiece diameter range | φ(3000-8000)mm |

| ★ | The driving capacity of the roller frame | 500T/per set |

| ★ | Roller Rotation Drive Capability | 500T/per set |

| ★ | 1,Drive Rotator specification(1 set) | |

| ☆ | 1.1 Rotary drive capability | 500T(1 set) |

| ☆ | 1.1.1 Brand and Model of Rotary Drive Inverter Motor | INVERTEK,2*11Kw Inverter motor |

| ☆ | 1.1.2 Brand and Model of Rotary Drive Reducer | Jiangsu Kaibo |

| ☆ | 1.1.3 Linear speed of roller rotation | (120-1200)mm/min |

| ☆ | 1.1.4 Rotating roller material | 45# steel forging |

| ☆ | 1.1.5 Outer diameter of roller | Φ800mm |

| ☆ | 1.1.6 Overall width of rollers | 380mm |

| ☆ | 1.1.7 Adjustment method of center distance of roller seat | Manual hierarchical adjustment |

| ☆ | 1.2 Driving capacity of the roller frame | 500T |

| ☆ | 1.2.1 Brand and Model of Travel Drive Reducer | Jiangsu Kaibo |

| ☆ | 1.2.2 Brand and Model of Travel Drive Motor | INVERTEK,2*5.5Kw(Double drive) |

| ☆ | 1.2.3 Walking wheel material | 45# steel wheel forgings |

| ☆ | 1.2.4 Heat treatment hardness and depth of walking wheels | Quenching and tempering, intermediate frequency heat treatment, HRC-42, depth 2mm |

| ☆ | 1.2.5 Inner single rim running wheel, inner gauge | 4000mm |

| ★ | 2,Technical specifications of driven wheel parts (2 sets) | |

| ☆ | 2.2 Rotating roller material | 45# steel wheel forgings |

| ☆ | 2.3 Outer diameter of roller | Φ800mm |

| ☆ | 2.4 Overall width of roller | 380mm |

| ☆ | 2.5 Adjustment method of center distance of roller seat | Manual hierarchical adjustment |

| ☆ | 2.6 inner single rim running wheel, inner gauge | 4000mm |

| ☆ | 2.7 Walking wheel material | 45# steel wheel forgings |

| ☆ | 2.8 Heat treatment hardness and depth of walking wheels | Quenching and tempering, intermediate frequency heat treatment, HRC-42, depth 2mm |

Features of Hydraulic fit up welding rotator:

1.Cylinder big heavy welding rotator's main body of the drum adopts 35# cast steel wheel, and the surface is inlaid with vulcanized rubber.

2.When assembling butt welding pipes/tanks/cylinders, the center angle of the them should be between 45°-110°. When it exceeds this range, it can be achieved by adjusting the center distance of the roller seat, and the center distance of the roller seat is adjusted through the screw hole.

3.There is a rail seat under the base of the roller frame, and the roller frame can be firmly fixed on the track by the screws on the side.

1.Cylinder big heavy welding rotator's main body of the drum adopts 35# cast steel wheel, and the surface is inlaid with vulcanized rubber.

2.When assembling butt welding pipes/tanks/cylinders, the center angle of the them should be between 45°-110°. When it exceeds this range, it can be achieved by adjusting the center distance of the roller seat, and the center distance of the roller seat is adjusted through the screw hole.

3.There is a rail seat under the base of the roller frame, and the roller frame can be firmly fixed on the track by the screws on the side.

CNC cutting equipment

H beam Box beam steel structure production lines

Complete sets of welding equipment.

Relying on advanced concepts, excellent technology, and exquisite craftsmanship, the company has formed a multi-variety and multi-series product structure.

Our products serve construction machinery, construction machinery, boilers and pressure vessels, steel structures, wind power and other industries, and the products are exported to Southeast Asia, the Middle East, Europe and the United States and many other countries.

Our company has passed ISO90001 quality system certification, ISO14001 environmental system certification