Basic Info.

Model NO.

BWJ-05

Max Eccentricity Distance

150mm

Tilting Angle

0-120°

Voltage

110V/220V

Condition

New

Function

Stainless Steel Pipe Flange Welding Positioner

Max Loading Weight

50kg

Other Names

Welding Postioner Turntables

Control Mode

CNC

Tilt Angle

0-120

Table Speed

0.1-5

Welding Machine

TIG Welding Machine

Lead Time

5 Days

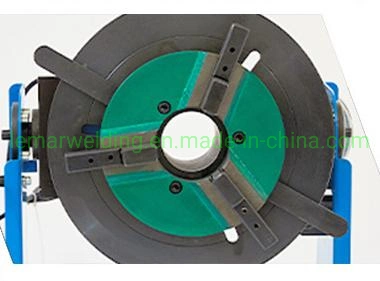

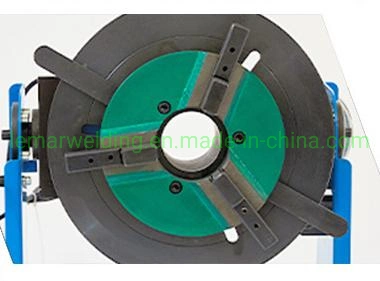

Suitable Chuck

Kd-150/200/300

Motor

Step Motor

Table Height

400mm

Optional

TIG MIG Mag Welder

Welder Holder

Yes

Oversize

Customized

Warranty

1 Year

Transport Package

Standard Package

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

3000PCS/Year

Packaging & Delivery

Package Size

60.00cm * 60.00cm * 60.00cm

Package Gross Weight

110.000kg

Product Description

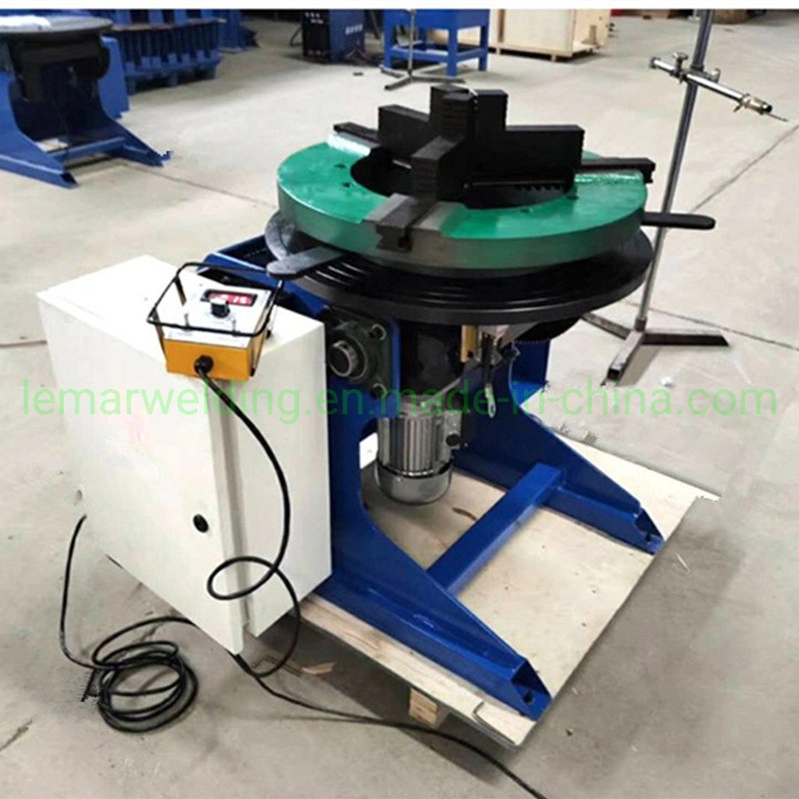

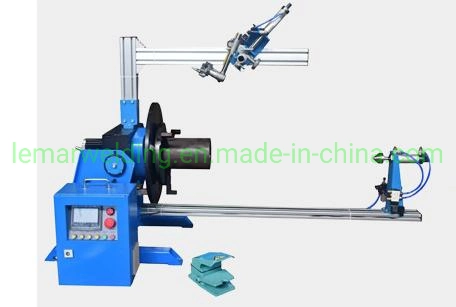

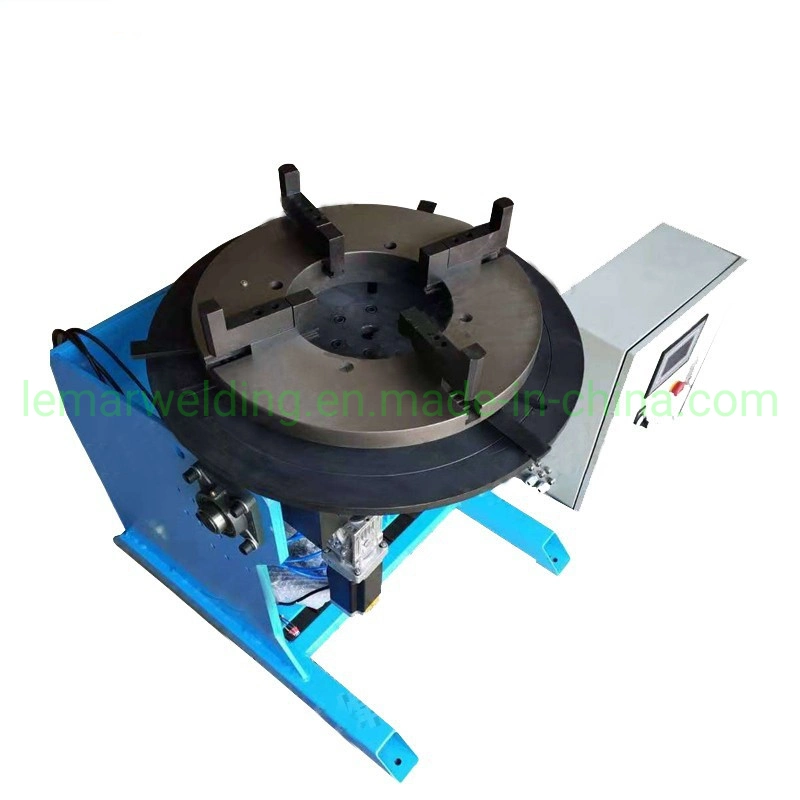

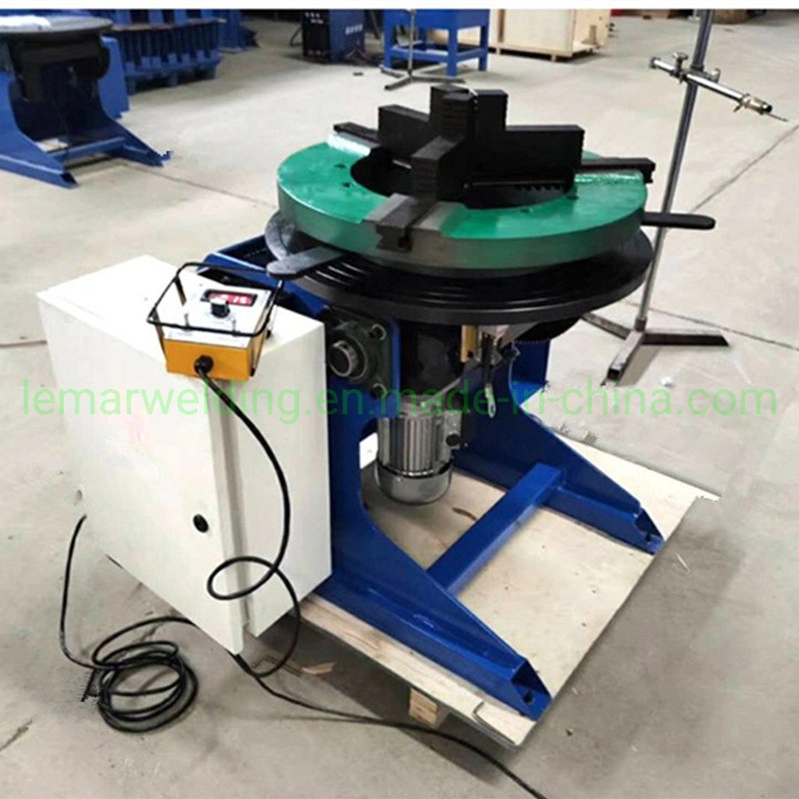

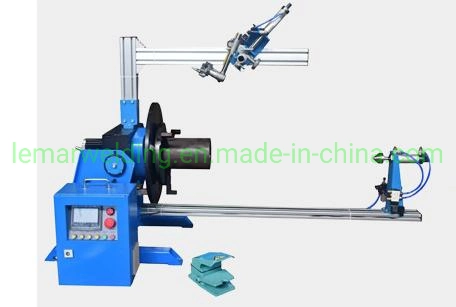

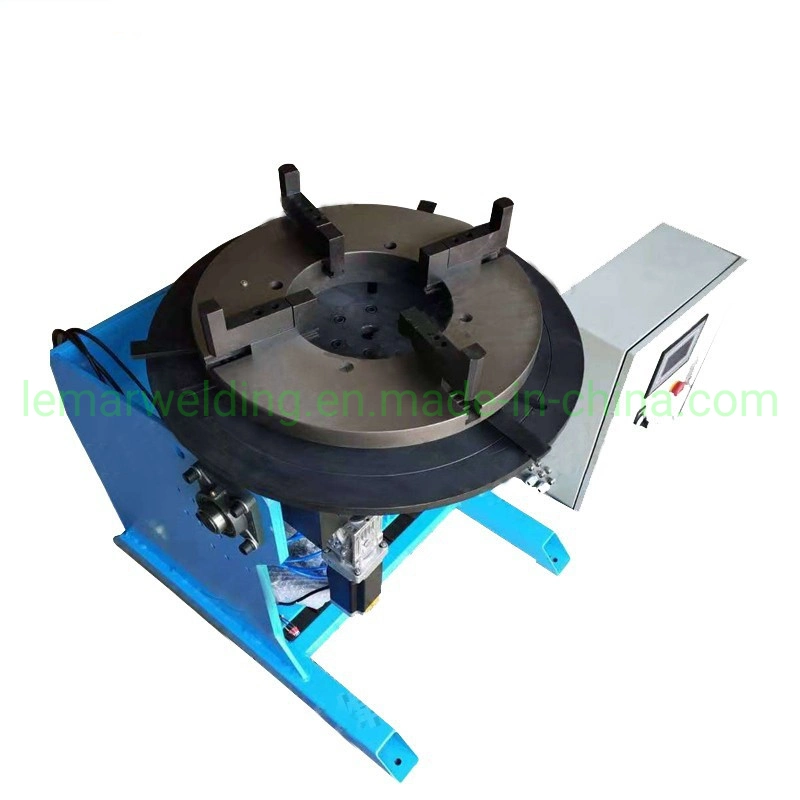

Automated Rotary Positioner Table Industrial Welding Turntables

How to choose Welding Positioner?

The core data of the selection of CNC transformer is mainly referred to welding data.

First of all, selecting the size of the welding positioners should consider the size of the workpiece (PIPE and FLANGE Diameter/Thickness/Length/Material) to select the diameter of the turntable;

If the welding table diameter is small, Pipe Diameter is larger and the Pipe weight is lighter, you can choose the small mini loading weight welding positioner to meet the tube welding.

Another situation is that when the Pipe Diater is large and the pipe or flange weight is heavier, it is necessary to choose a heavy duty CNC welding positioners according to the actual situation.

Large welding workpieces require Bigger Welding Turntable Diameter and Bigger Loading Weight, and a more stable base.

Wuxi Lemar Produce Welding Positioners 10kg/30kg/50kg/300kg/600kg/1000kg up to 15tons Welding Tables.

Specifications:

Specifications:

Note:The worktable diameter can be customized according to your needs

360° Rotating and 0-135° Flip Welding Positioners is currently widely used structural form in welding industry.

360° Rotating and 0-135° Flip Welding Positioners is currently widely used structural form in welding industry.

1. This dual -axis welding variable welding benchtop positioner has an overall flip freedom, which can flip the work to the ideal welding position for welding.

2. Flip and rotation are driven by two axises. In addition to turning around the axis of the workpiece, the workbench welding tables can also be tilted or flipped.

3. It can adjust the welds of various locations on the welding parts to the horizontal or "ship type" easy welding position, and cooperate with the Welding Chuck and Pneumatic Welding Torch Holder. welding.

4.CNC welding positioners or normal welding positioners are mainly used for welding of some pipe disks.

Generally, it is not required to be fixed on the foundation. It is convenient to move. It is currently widely used in structural forms.

How to choose Welding Positioner?

The core data of the selection of CNC transformer is mainly referred to welding data.

First of all, selecting the size of the welding positioners should consider the size of the workpiece (PIPE and FLANGE Diameter/Thickness/Length/Material) to select the diameter of the turntable;

If the welding table diameter is small, Pipe Diameter is larger and the Pipe weight is lighter, you can choose the small mini loading weight welding positioner to meet the tube welding.

Another situation is that when the Pipe Diater is large and the pipe or flange weight is heavier, it is necessary to choose a heavy duty CNC welding positioners according to the actual situation.

Large welding workpieces require Bigger Welding Turntable Diameter and Bigger Loading Weight, and a more stable base.

Wuxi Lemar Produce Welding Positioners 10kg/30kg/50kg/300kg/600kg/1000kg up to 15tons Welding Tables.

| No. | 50kg Normal Welding positioner | 50kg Timing Welding positioner | 50kg CNC Welding positioner |

| Loading weight | 50kg | 50kg | 50kg |

| Turntable diameter | 315mm | 315mm | 315mm |

| Drive motor | DC 220V 120W | DC 220V 120W | 86 stepper motor |

| Turntable height | 400mm | 400mm | 400mm |

| Tilt angle | 0-90° | 0-90° | 0-90° |

| Turntable speed | 1-15rpm/0.05-5rpm/0.2-2.5rpm | 1-15rpm/0.05-5rpm/0.2-2.5rpm | 0.01-5.00rpm |

| Using for | Manual welding/Cutting/Painting | Automatic welding/Cutting/Painting | Precision automatic welding |

| Standard supply | Welding postiioner,Control box,Foot switch,Wire power,Manual,Certificate | ||

| Optional | Welding chuck 3 jaw or customized/Pneumatic welding torch holder/Manual torch holder/Pneumatic tail/welding rotator | ||

1. This dual -axis welding variable welding benchtop positioner has an overall flip freedom, which can flip the work to the ideal welding position for welding.

2. Flip and rotation are driven by two axises. In addition to turning around the axis of the workpiece, the workbench welding tables can also be tilted or flipped.

3. It can adjust the welds of various locations on the welding parts to the horizontal or "ship type" easy welding position, and cooperate with the Welding Chuck and Pneumatic Welding Torch Holder. welding.

4.CNC welding positioners or normal welding positioners are mainly used for welding of some pipe disks.

Generally, it is not required to be fixed on the foundation. It is convenient to move. It is currently widely used in structural forms.