Basic Info.

Model NO.

BWJ-6

Max Eccentricity Distance

150mm

Tilting Angle

0-90°

Voltage

110V/220V

Condition

New

Function

Pipe Flange Welding Turning Table

Power Input

380V 50/60Hz

Horizontal Loading Weight

600kg

Vertical Loading Weight

300kg

Rotation Speed

0.09-0.9rpm

Tilting Motor

1.1kw

Worktable Diameter

1000mm

Rotation Motor

0.75kw

Suitable Chuck

200/300/400mm/500mm 3 Jaw Welding Chuck

Foot Pedal

Yes

Lead Time

5 Days

Pedal Switch

Yes

Optional

TIG MIG Mag Welding Machine

Postioner Type

Seat Type

in Stock

Yes

Transport Package

Standard Package

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

30000PCS/Year

Packaging & Delivery

Package Size

170.00cm * 90.00cm * 550.00cm

Package Gross Weight

1100.000kg

Product Description

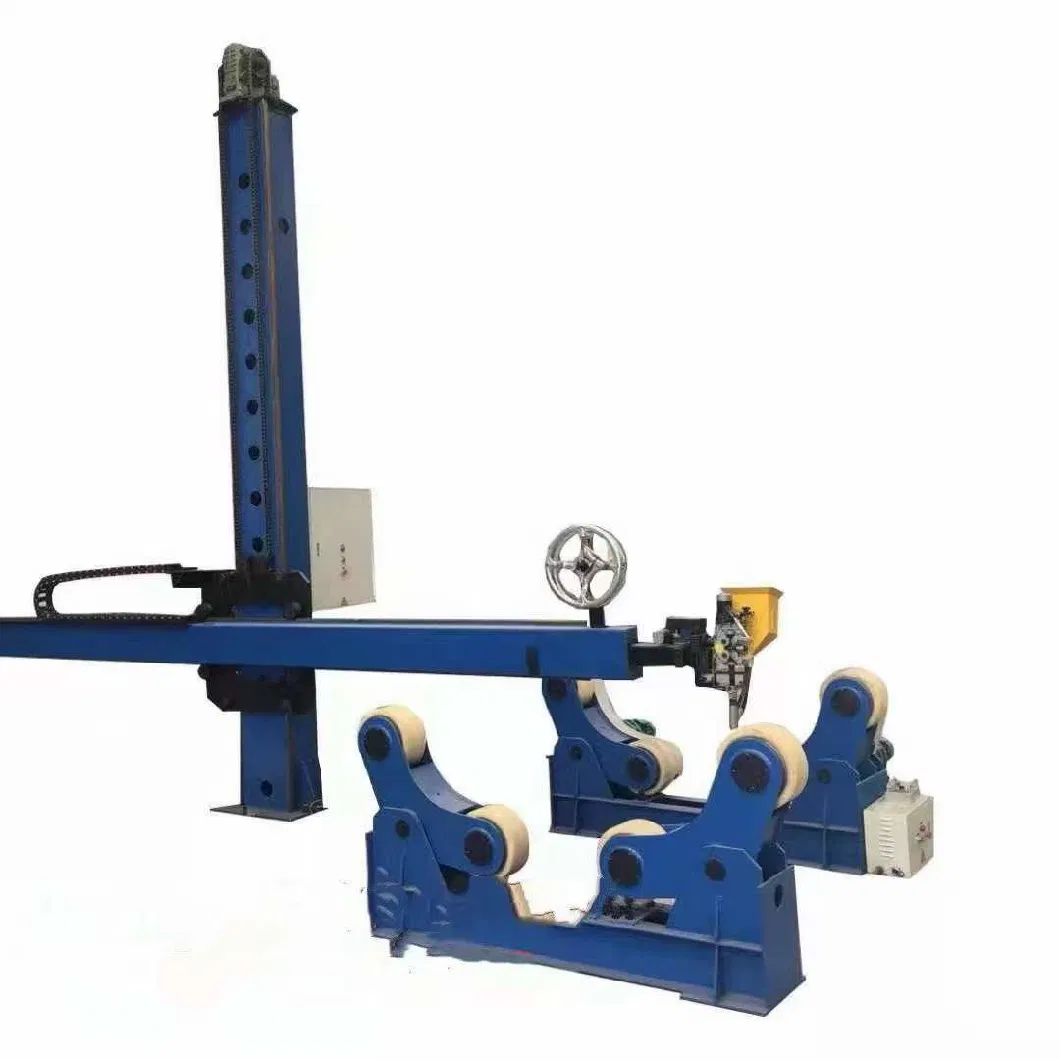

Automatic Pipe Flange welding table Welding Positioners with Foot pedal and 3 jaw welding chuck

The working principle of the automatic rotating turntable is that through the rotation and flipping of the worktable, the workpiece is placed in the best welding or assembly position, which improves the welding efficiency and quality of TIG MIG pipe flange welding.

Features: 10kg-15T 0-135° automatic turning tilting welding positioner frequency conversion stepless speed regulation, free turning, wide applicability.

Scope of application: It is suitable for welding rotary bodies of various shafts, discs, and cylinders.

The turning turntable can be fixed on the workbench or special tooling for manual welding by clamping the workpiece, and can also be used in conjunction with a welding manipulator to realize automatic welding, and can also be used for cutting, grinding, assembling, testing and other processes. Specifications:

A rotating mechanism, a turning mechanism, a frame, and an electronic control system make up a seat-type positioner.

To position the workpiece for the best welding or assembly, it flips and rotates the worktable.

The worktable rotates with frequency conversion used for stepless speed management.

A hydraulic cylinder or a sector gear is used to tilt the worktable. The worktable may rotate between 0 and 120 degrees.

It is capable of achieving joint control with a welding or operating equipment.

Push-button digital control, switch digital control, and switch relay control are the three configuration types that the control system can support.

Why choose Wuxi Lemar?What can Lemar do for clients?

Why choose Wuxi Lemar?What can Lemar do for clients?

Our Product

Our company Wuxi Lemar is mainly engaged in research and development, manufacture and sale, CNC Plasma cutting machine and Automatic welding equipment such as H-beam welding production line (light type, heavy type), box beam welding production line, horizontal assembly&welding production line,adjustable welding rotator, self-aligning welding turning rolls,seat type welding positioner,robotic welding turning assembly positioner,Customized positioners,3 jaw 4 jaw welding chuck,Straight seam welding machines,Circular seam welding machines,Column and boom TIG MIG SAW Tank and vessel welding manipulators,etc,

Our Product Application

The products are widely used in steel structure, shipbuilding, bridge building, boiler, chemical industry, metallurgy, electrical power industries etc.

Our Certificate

We have passed the ISO CE SGS testing standard, besides, our machine have honor to won many patents, like H-beam manufacturing equipment patents, welding positioner,welding rotator,column and boom rotate welding manipulator patents and etc.

Our machines have been exported to USA,UK,Canada,Russia,Poland, France,Kazakhstan, Pakistan, Bulgaria, Colombia,Brazil,etc.

Our service

All of our machines have one year warranty,we are 24 hours online for after sales service,we can send engineers to client's sites to resolve problems.

The working principle of the automatic rotating turntable is that through the rotation and flipping of the worktable, the workpiece is placed in the best welding or assembly position, which improves the welding efficiency and quality of TIG MIG pipe flange welding.

Features: 10kg-15T 0-135° automatic turning tilting welding positioner frequency conversion stepless speed regulation, free turning, wide applicability.

Scope of application: It is suitable for welding rotary bodies of various shafts, discs, and cylinders.

The turning turntable can be fixed on the workbench or special tooling for manual welding by clamping the workpiece, and can also be used in conjunction with a welding manipulator to realize automatic welding, and can also be used for cutting, grinding, assembling, testing and other processes. Specifications:

| MODEL | UNIT | BWJ-1 | BWJ-3 | BWJ-6 | BWJ-12 |

| Power input | / | 1 Phase AC115/230V 3P 380V 50/60Hz | |||

| Horizontal loading capacity | Kg | 100 | 300 | 600 | 1200 |

| Vertical loading capacity | Kg | 50 | 150 | 300 | 600 |

| Working table diameter | mm | 400 | 600 | 1000 | 1200 |

| Working table tilting angle | ° | 0-90 | 0-90 | 0-90 | 0-120 |

| Working table Rotation speed | r/min | 0.1-1 | 0.09-0.9 | 0.09-0.9 | 0.05-0.5 |

| Rotation motor | 200W | 0.37KW | 0.75KW | 1.1KW | |

| Applicable chuck | / | KC-200/300 | KD-200/300/400 | KD-200/300/400/500 | Customized |

To position the workpiece for the best welding or assembly, it flips and rotates the worktable.

The worktable rotates with frequency conversion used for stepless speed management.

A hydraulic cylinder or a sector gear is used to tilt the worktable. The worktable may rotate between 0 and 120 degrees.

It is capable of achieving joint control with a welding or operating equipment.

Push-button digital control, switch digital control, and switch relay control are the three configuration types that the control system can support.

Our Product

Our company Wuxi Lemar is mainly engaged in research and development, manufacture and sale, CNC Plasma cutting machine and Automatic welding equipment such as H-beam welding production line (light type, heavy type), box beam welding production line, horizontal assembly&welding production line,adjustable welding rotator, self-aligning welding turning rolls,seat type welding positioner,robotic welding turning assembly positioner,Customized positioners,3 jaw 4 jaw welding chuck,Straight seam welding machines,Circular seam welding machines,Column and boom TIG MIG SAW Tank and vessel welding manipulators,etc,

Our Product Application

The products are widely used in steel structure, shipbuilding, bridge building, boiler, chemical industry, metallurgy, electrical power industries etc.

Our Certificate

We have passed the ISO CE SGS testing standard, besides, our machine have honor to won many patents, like H-beam manufacturing equipment patents, welding positioner,welding rotator,column and boom rotate welding manipulator patents and etc.

Our machines have been exported to USA,UK,Canada,Russia,Poland, France,Kazakhstan, Pakistan, Bulgaria, Colombia,Brazil,etc.

Our service

All of our machines have one year warranty,we are 24 hours online for after sales service,we can send engineers to client's sites to resolve problems.