Basic Info.

Model NO.

BWJ

Welding Tilter Type

Flexible Combination

Condition

New

Model

Bwj-1

Function

Positioner for Pipe Flange Welding

Loading Weight

100kg

Input Power

AC 220V

Vertical Loading Weight

50kg

Horizontal Loading Weight

100kg

Welding Positioner Diameter

500mm

Hole Diameter

240mm

Positioner Height

650mm

Rotating Speed

0.2-2rpm

Rotating Motor

250W

Welding Machine

Laser Welding Machine

Tilt Mode

Manual or Electric

Laser Voltage

220V

Lead Time

3 Days

Transport Package

Wooden

Trademark

Lemar

Origin

Wuxi, China

HS Code

85158090

Production Capacity

1000 PCS/Year

Product Description

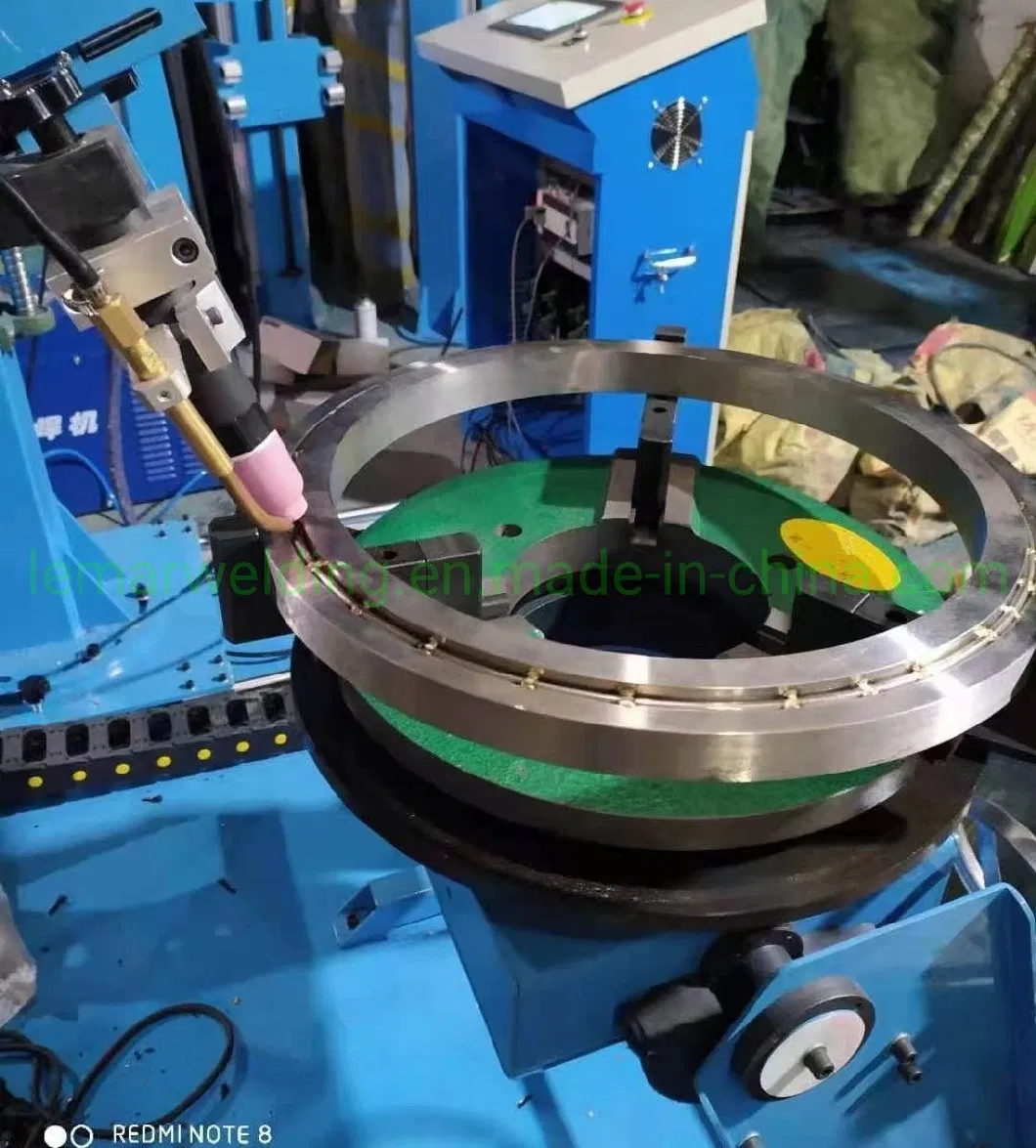

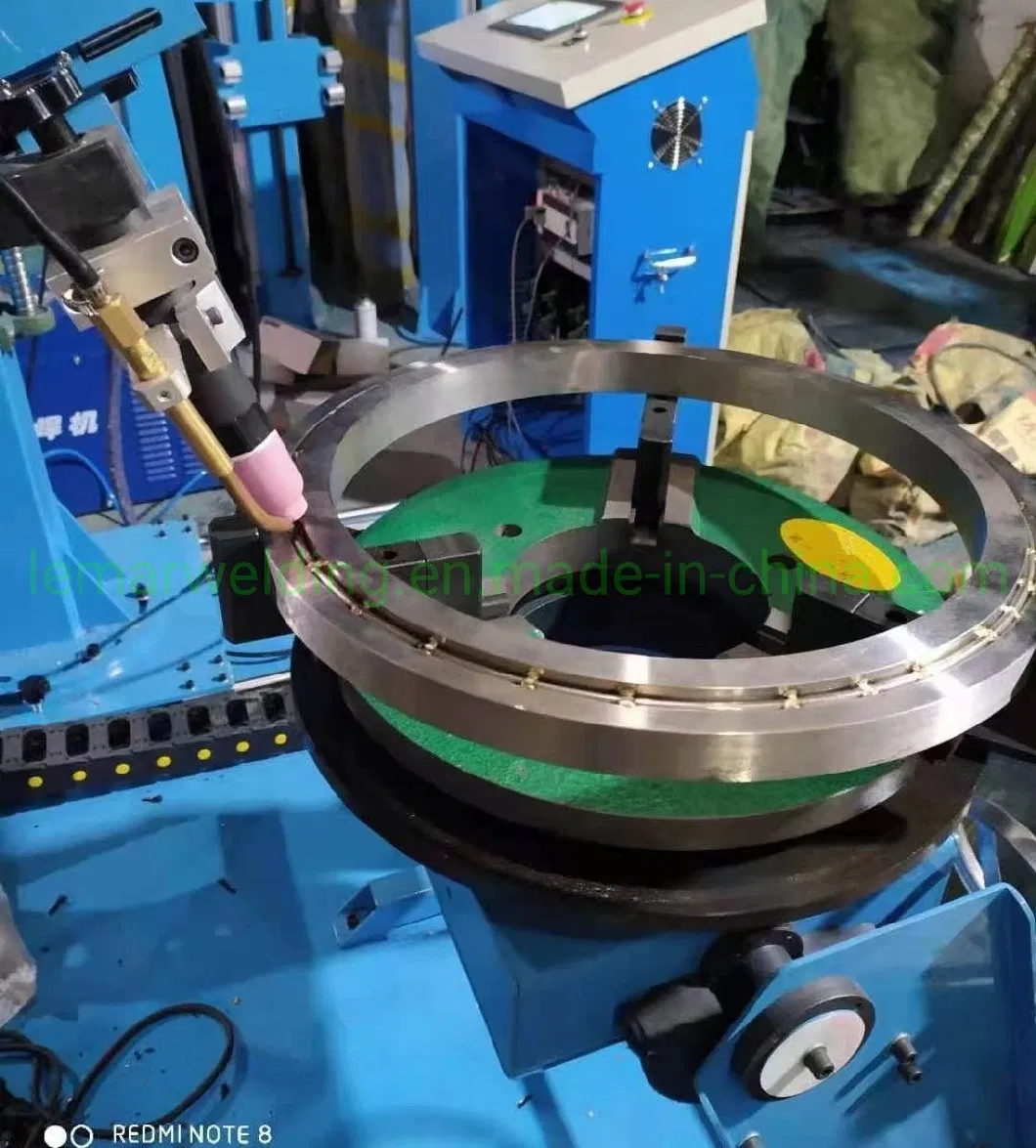

Automatic TIG welding positioners with 65mm diameter through hole

As a professional welding positioner turntable manufacturers Wuxi Lemar Machinery Equipments Co.,Ltd can supply you 10kg~20T loading weight tig or laser welding positioners.

Welding locator description:

Use the mechanical welding positioner to control and rotate the workpiece 360 degrees so that the operator can weld the metal sheet correctly and conveniently, usually by TIG/MIG/CO2/SAW welding.

Improve your manufacturing process easily by adding a weld positioner to increase productivity and weld quality.

Compared with other welding techniques, the main advantages of laser welding are:

Compared with other welding techniques, the main advantages of laser welding are:

1. Fast speed, large depth and small deformation.

2. It can be welded at room temperature or under special conditions, and the welding equipment is simple to install.

3. It can weld refractory materials such as titanium, quartz, etc., and can weld heterogeneous materials with good effect.

4. After the laser is focused, the power density is high. When welding high-power devices, the aspect ratio can reach 5:1, and the highest can reach 10:1.

5. Micro-welding is possible. After the laser beam is focused, a very small spot can be obtained, and it can be precisely positioned. It can be applied to the assembly and welding of micro and small workpieces in mass automatic production. (The smallest spot can reach 0.1mm)

6. It can weld inaccessible parts, and implement non-contact long-distance welding, which has great flexibility.

7. The laser beam is easy to realize beam splitting according to time and space, and can perform multi-beam simultaneous processing and multi-station processing, which provides conditions for more precise welding.

Specification details

Specification details

Portable laser welding machine specification:

Portable laser welding machine specification:

With the DIY Spin Welding Positioner you can easily work with TIG or MIG welding processes.

With the DIY Spin Welding Positioner you can easily work with TIG or MIG welding processes.

During machining operations, the angle of the workpiece can be adjusted in different ways.

For workpieces that are too long or have a large diameter, you can choose to match them with welding chucks (3 jaw chucks, 4 jas chucks or customized chucks), which are convenient for welders to rotate, lift, and adjust the working range.

More questions please feel free to contact us directly through here or mail!

As a professional welding positioner turntable manufacturers Wuxi Lemar Machinery Equipments Co.,Ltd can supply you 10kg~20T loading weight tig or laser welding positioners.

Welding locator description:

Use the mechanical welding positioner to control and rotate the workpiece 360 degrees so that the operator can weld the metal sheet correctly and conveniently, usually by TIG/MIG/CO2/SAW welding.

Improve your manufacturing process easily by adding a weld positioner to increase productivity and weld quality.

1. Fast speed, large depth and small deformation.

2. It can be welded at room temperature or under special conditions, and the welding equipment is simple to install.

3. It can weld refractory materials such as titanium, quartz, etc., and can weld heterogeneous materials with good effect.

4. After the laser is focused, the power density is high. When welding high-power devices, the aspect ratio can reach 5:1, and the highest can reach 10:1.

5. Micro-welding is possible. After the laser beam is focused, a very small spot can be obtained, and it can be precisely positioned. It can be applied to the assembly and welding of micro and small workpieces in mass automatic production. (The smallest spot can reach 0.1mm)

6. It can weld inaccessible parts, and implement non-contact long-distance welding, which has great flexibility.

7. The laser beam is easy to realize beam splitting according to time and space, and can perform multi-beam simultaneous processing and multi-station processing, which provides conditions for more precise welding.

| 100kg Welding positioner Specifications | |

| Model | BWJ-1 |

| Input power | AC220V |

| Loading weight | Horizontal 100kg/Vertical 50kg |

| Positioner table diameter | 500mm |

| Hole diameter | 90/170/240mm |

| Positioner table height | 650mm |

| Rotating speed | 0.2-2rpm |

| Rotating motor | 250W |

| Tilt angle | 0-90 degree |

| Tilt mode | Manual/Electric |

| Positioner weight | 110Kg |

| Suitable welding chuck | KP-200/300/400/500 |

| Control mode | CNC Control welding positioner |

| Material | Protective gas | Thickness(mm) | ||

| Model | 1000w | 1500W | 2000w | |

| Aluminum plate | N2 | 0.5-2 | 0.5-2.5 | 0.5-3mm |

| Stainless steel | Ar N2 | 0.5-2.5 | 0.5-3 | 0.5-3.5 |

| Carbon steel | CO2 | 0.5-2.5 | 0.5-3 | 0.5-3.5 |

| Galvanized plate | Ar | 0.5-2.5 | 0.5-3 | 0.5-3.5 |

During machining operations, the angle of the workpiece can be adjusted in different ways.

For workpieces that are too long or have a large diameter, you can choose to match them with welding chucks (3 jaw chucks, 4 jas chucks or customized chucks), which are convenient for welders to rotate, lift, and adjust the working range.

More questions please feel free to contact us directly through here or mail!