Basic Info.

Model NO.

HB

Welding Turning Rolls Type

Self-Adjusting

Welding Tilter Type

Flexible Combination

Condition

New

Certificate

CE, ISO

Function

for Welding

Color

Blue; or as Customers′ Requirement

Advantage

Stepless Speed Regulation for Frequency Conversion

Transport Package

Standard

Specification

Standard

Trademark

Datang

Origin

China

HS Code

84688000

Production Capacity

30 Sets /Month

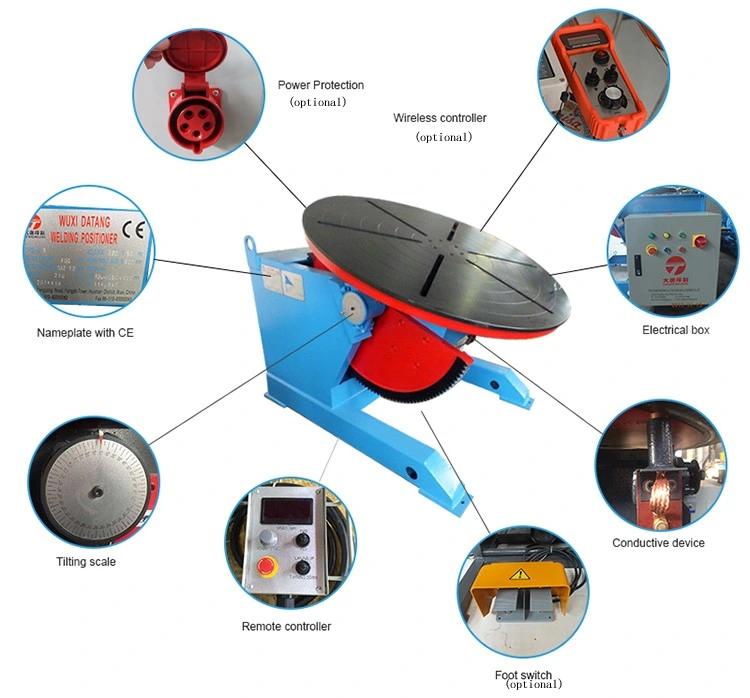

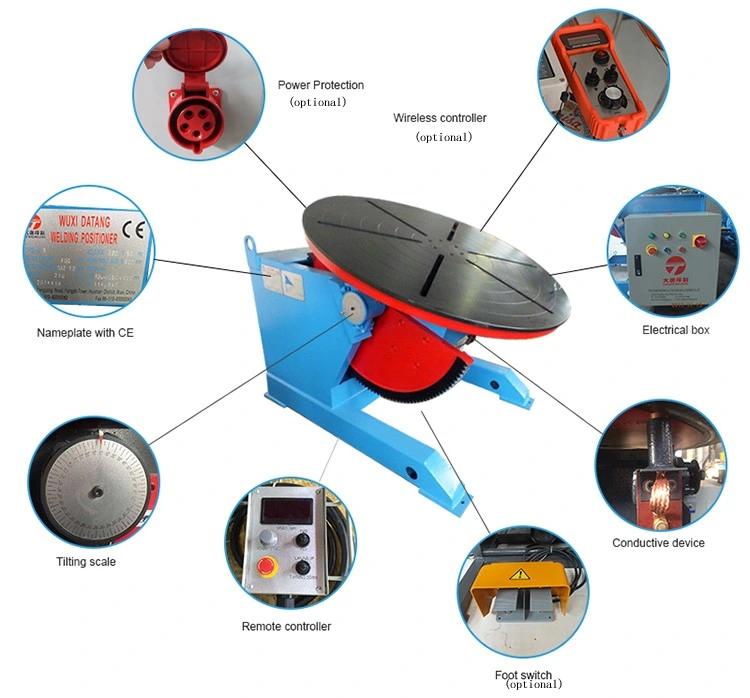

Product Description

Welding Positioner

This welding positioner is mainly used for the accessories and parts welding and assembling. It makes the workpiece

at the suitable position for welding or assembling by the working table overturning and rotating, which is one of

necessary equipments for the company manufacturing. During the manufacturing, it can improve the welding quality,

reducing the workpiece moving time and the labor working force, which is one of best way to improve the working

effeciency. This equipment has the advanced structure, easy controlling and convenient operation, and good for

improving the welding quality, which is the ideal equipment to improving the welding quality.

This welding positioner is mainly used for the accessories and parts welding and assembling. It makes the workpiece

at the suitable position for welding or assembling by the working table overturning and rotating, which is one of

necessary equipments for the company manufacturing. During the manufacturing, it can improve the welding quality,

reducing the workpiece moving time and the labor working force, which is one of best way to improve the working

effeciency. This equipment has the advanced structure, easy controlling and convenient operation, and good for

improving the welding quality, which is the ideal equipment to improving the welding quality.

| NO. | Technical Parameter | Type | ||||||||||

| HB1 | HB3 | HB6 | HB12 | HB30 | HB50 | HB100 | HB150 | HB200 | ||||

| 1 | Rated loading (Kg) | 100 | 300 | 600 | 1200 | 3000 | 5000 | 10000 | 15000 | 20000 | ||

| 2 | Max eccenteric Distance(mm) | 50 | 100 | 200 | 200 | 250 | 250 | |||||

| 3 | Max distance of Gravity center (mm) | 150 | 200 | 300 | 400 | 500 | 600 | |||||

| 4 | Working table size (mm) | φ400 | φ600 | φ1000 | φ1200 | φ1400 | φ1500 | φ1800 | φ2000 | φ2200 | ||

| 5 | The amount of table T-beam groove | 4 | 6 | |||||||||

| 6 | Tilting angle (°) | 0°~+90° | 0°~+120° | |||||||||

| 7 | Rotating speed (rpm) | 0.2~2 | 0.15~1.5 | 0.1~1 | 0.05~0.5 | 0.03~0.3 | ||||||

| 8 | Rotating Power(KW) | 0.18 | 0.18 | 0.75 | 0.75 | 1.5 | 2.2 | 3 | 4 | 5.5 | ||

| 9 | Tilting speed (rpm) | 0.8 | 0.5 | 0.3 | 0.14 | |||||||

| 10 | Tilting Power(kW) | 0.75 | 1.1 | 2.2 | 3 | 4 | 5.5 | 7.5 | ||||

| 11 | Structure of rotating axes | Direct connection of reducer | Tilting support | |||||||||

| 12 | Electricity (A) | 600 | 600 | 600 | 600 | 1000 | 1000 | 2000 | 2000 | 2000 | ||

| 13 | Height of the tilting center h(mm) | 300 | 457 | 712 | 735 | 1100 | 1292 | 1420 | 1570 | 1570 | ||

| 14 | Max diameter of workpiece (mm) | 550 | 850 | 1350 | 1400 | 2000 | 2500 | 2700 | 3000 | 3000 | ||

| 15 | Speed adjusting way | Rotating speed VFD | ||||||||||

| Tilting speed constant | ||||||||||||