Basic Info.

Model NO.

BWJ

Motor

Servo

Vertical Load

500kg

Horizontal Load

300kg

Flip Angle

0-360

Reducer Type

RV Reducer

Servo Motor

1.5kw

Robot Brand

Kuka,Funuc etc.

Lead Time

30 Days

Height Adjustment

Customized

Length Adjustment

Customized

Exported to

Europe,USA,UK,Russia etc

Warranty

1 Year

Transport Package

Wooden

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Product Description

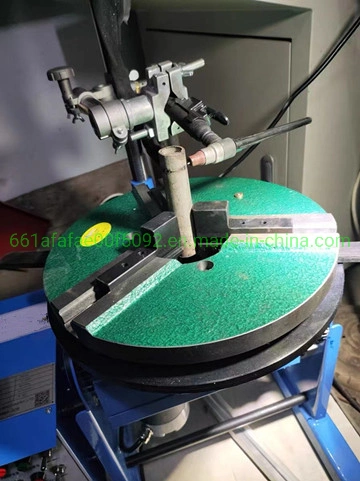

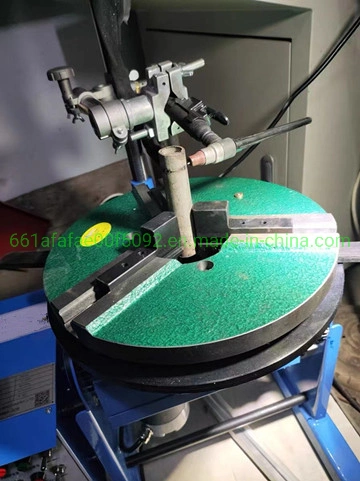

Headstock Tailstock Elevating Tilt Positioners for Assembly Handling Welding

The Headstock tailstock robot welding servo positioner is primarily made up of a permanent base that is integrated, rotating headstock and tail boxes, welding positioner frames, AC servo motors, RV precision reducers, conductive mechanisms, protective shields, and electrical control systems, among other components.

Features of Head and tailstock positioners with single or multi-axis servo motors

1. Reduce the labor intensity of operators

2. Ensure high quality product welding

3. Lower-skilled workers can be selected to reduce labor costs

4. Wide range of applications; robots can automatically weld large and small workpieces

Specification of Robot welding positioner:

There are two types of head-to-tail welding positioners-----Lifting type and Fixed type Robot welding positioner.

There are two types of head-to-tail welding positioners-----Lifting type and Fixed type Robot welding positioner.

The head-to-tail standard positioner can be raised and rotated electrically, and it clamps overly-long workpieces at both ends. The workpiece can be raised, lowered, and rotated while mounted, and it is positioned in the lowest feasible position.

Safety, productivity, and workability are all increased because the head-to-tail welding positioner can be placed in a position where the process is comparatively simple.

The Headstock tailstock robot welding servo positioner is primarily made up of a permanent base that is integrated, rotating headstock and tail boxes, welding positioner frames, AC servo motors, RV precision reducers, conductive mechanisms, protective shields, and electrical control systems, among other components.

Features of Head and tailstock positioners with single or multi-axis servo motors

1. Reduce the labor intensity of operators

2. Ensure high quality product welding

3. Lower-skilled workers can be selected to reduce labor costs

4. Wide range of applications; robots can automatically weld large and small workpieces

Specification of Robot welding positioner:

| Model | BWJ-250 | BWJ-500 | BWJ-1000 | BWJ-2501 | BWJ-2502 | BWJ-1001 |

| Max loading weight | 250kg | 500kg | 1000kg | 250kg | 500kg | 1000kg |

| Height of spindle center to base plate | 700mm | 700mm | 700mm | 700mm | 700mm | 700mm |

| Positioner size | 1800*800mm | 1800*800mm | 1800*800mm | 2500*800mm | 2500*800mm | 2500*800mm |

| Rotating speed | 60°/s | 60°/s | 40°/s | 60°/s | 60°/s | 40°/s |

| Repeatability | ±1.0arc/m | ±1.0arc/m | ±1.2arc/m | ±1.0arc/m | ±1.0arc/m | ±1.2arc/m |

| Rotating angle | ±180° | ±180° | ±180° | ±180° | ±180° | ±180° |

| Eccentricity | <=150mm | <=150mm | <=100mm | <=150mm | <=150mm | <=100mm |

| Center of gravity | <=300 | <=300 | <=200 | <=300 | <=300 | <=200 |

The head-to-tail standard positioner can be raised and rotated electrically, and it clamps overly-long workpieces at both ends. The workpiece can be raised, lowered, and rotated while mounted, and it is positioned in the lowest feasible position.

Safety, productivity, and workability are all increased because the head-to-tail welding positioner can be placed in a position where the process is comparatively simple.