Basic Info.

Model NO.

BWJ-10

Condition

New

Function

Stainless Steel Pipe Flange Welding Positioner

Max Loading Weight

100kg

Other Names

Welding Postioner Turntables

Control Mode

CNC

Tilt Angle

0-120

Table Speed

0.1-5

Welding Machine

TIG Welding Machine

Lead Time

5 Days

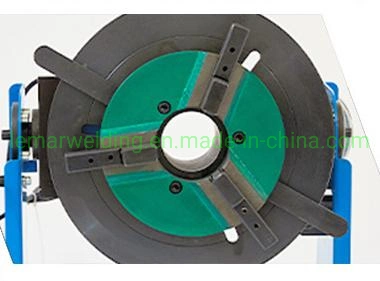

Suitable Chuck

Kd-150/200/300

Motor

Step Motor

Table Height

400mm

Optional

TIG MIG Mag Welder

Welder Holder

Yes

Oversize

Customized

Warranty

1 Year

Transport Package

Standard Package

Trademark

Lemar

Origin

Wuxi, China

HS Code

8428909090

Production Capacity

3000PCS/Year

Product Description

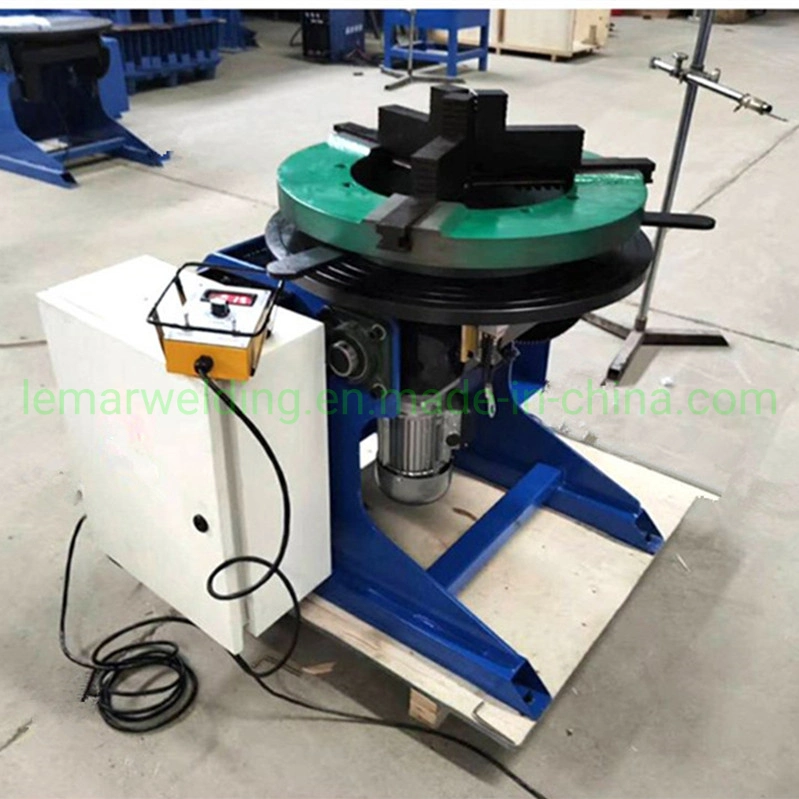

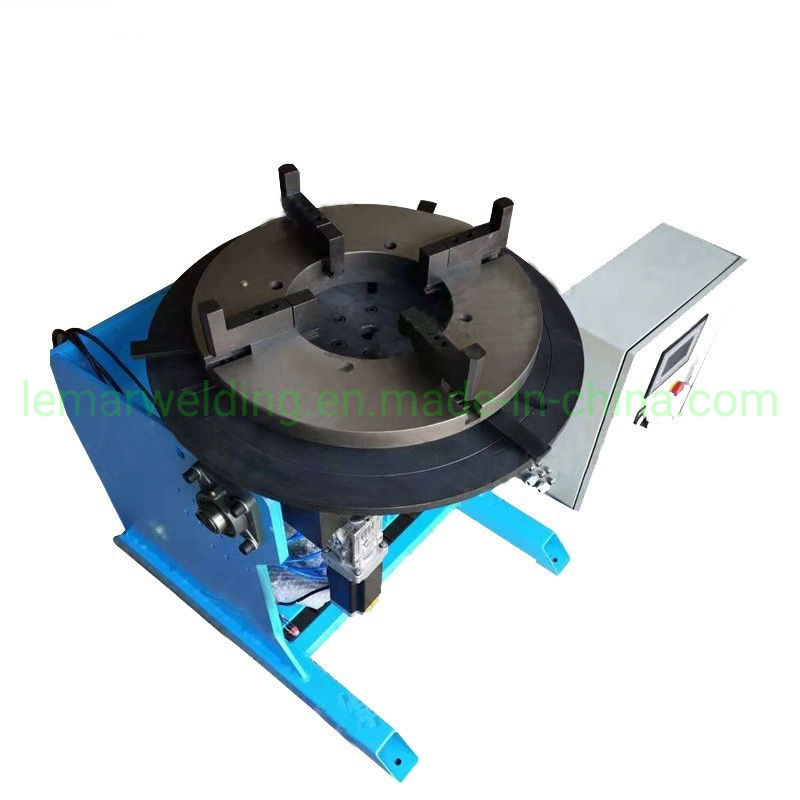

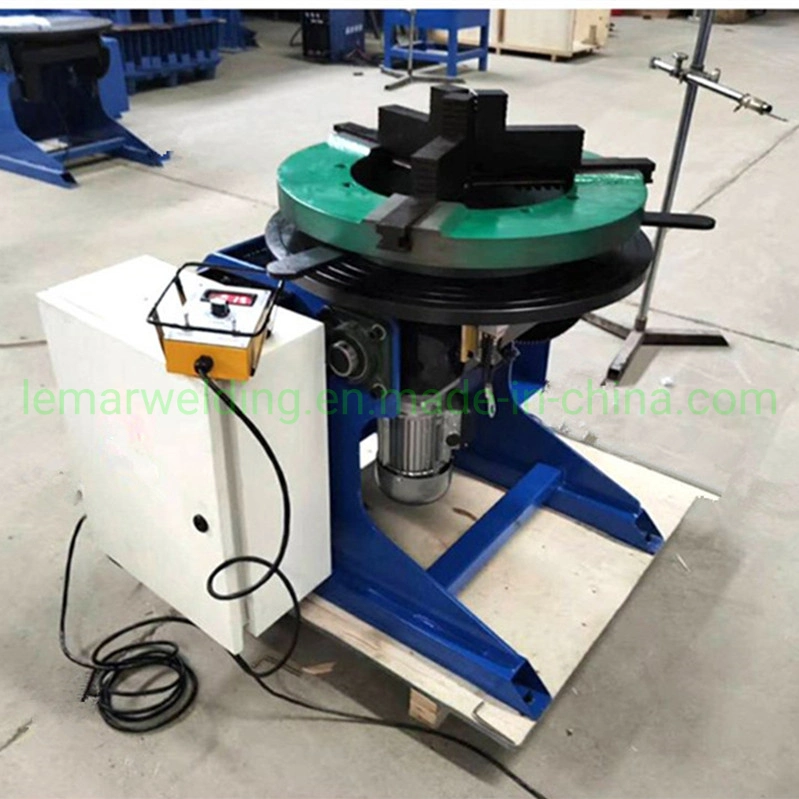

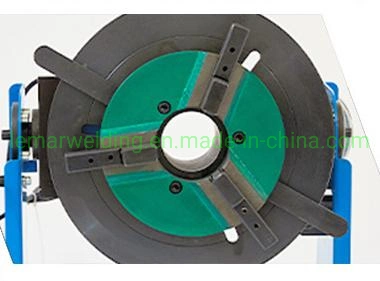

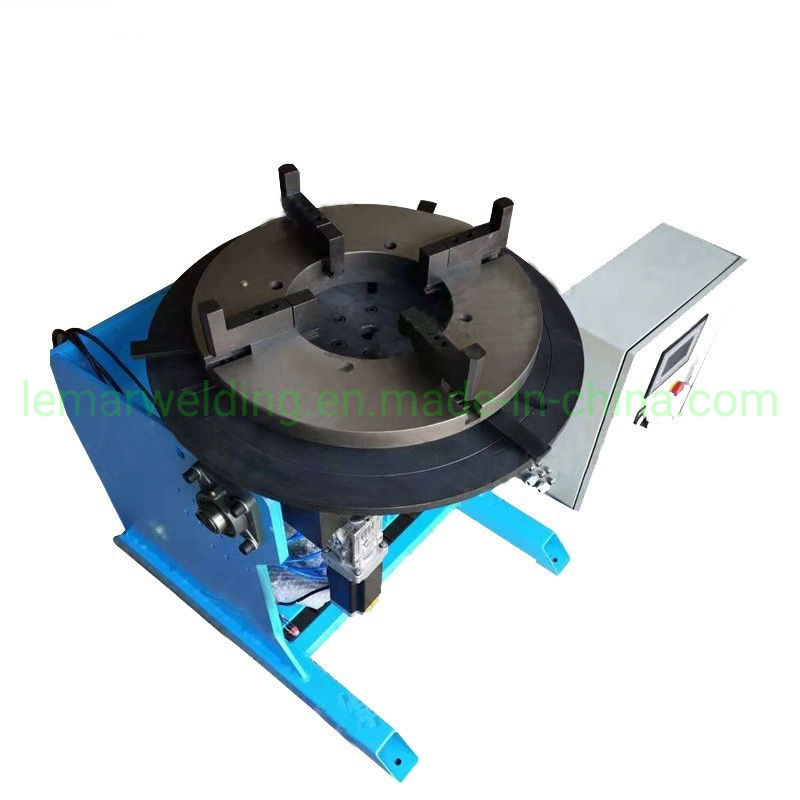

Rotary Welding positioner Turntable With Self-centering 3 jaw Lathe chuck

The welding positioners are indispensable auxiliary equipment for the tube welding and the flange welding industry.

It has the following categories:

(1) CNC bentchtop welding positioners

(2) Double axis turning and flipping welding positioners

(3) Head and tail dual rotation welding positioners

(4) L -shaped dual -rotating welding positioners

(5) C type dual rotation welding positioners

(7) Robotic welding turning positioners

Specifications:

Specifications:

Note:The worktable diameter can be customized according to your needs

What should you pay attention to when you are going to use welding positioner?

What should you pay attention to when you are going to use welding positioner?

1. Safety instructions: The operator needs to wear a safe protective gear, the welding turning positioners of different specifications, their load capacity is also different.

2. Checking: Before use the pipe positioners, check whether the power cord of it is connected to ensure that the ground wire is not damaged to prevent the leakage accident, prevent the power cord from good, avoid entanglement, prevent personnel from preventing personnel from being prevents personnel from being entangled, and prevent personnel from preventing personnel.

Check whether the nuts, bolts, etc. of all fixtures of the welding positioners are tightened, and check whether each axis is loose and tighten; check whether the reducer and the driver device are running normally.

3. The turntable can fix a dedicated welding chuck or other tools on the workbench to clamp the workpiece (pipe flange)for manual welding. The welding positioners can also be used with welding operators to achieve automatic welding and is widely used in the process of welding, cutting, polishing, assembly, painting, and detection.

4. Operate according to your own carrying capacity. The model of the welding turning table is different, and its carrying capacity is also different. Users need to choose the appropriate welding variable position according to their own workpiece specifications, which is conducive to ensuring the stability of the rotation.

The welding positioners are indispensable auxiliary equipment for the tube welding and the flange welding industry.

It has the following categories:

(1) CNC bentchtop welding positioners

(2) Double axis turning and flipping welding positioners

(3) Head and tail dual rotation welding positioners

(4) L -shaped dual -rotating welding positioners

(5) C type dual rotation welding positioners

(7) Robotic welding turning positioners

| No. | 100kg CNC Welding positioner |

| Loading weight | 50kg |

| Turntable diameter | 400mm |

| Drive motor | 86 stepper motor |

| Turntable height | 400mm |

| Tilt angle | 0-120° |

| Turntable speed | 0.01-5.00rpm |

| Using for | Precision automatic welding |

| Standard supply | Welding postiioner,Control box,Foot switch,Wire power,Manual,Certificate |

| Optional | Welding chuck 3 jaw or customized/Pneumatic welding torch holder/Manual torch holder/Pneumatic tail/welding rotator |

1. Safety instructions: The operator needs to wear a safe protective gear, the welding turning positioners of different specifications, their load capacity is also different.

2. Checking: Before use the pipe positioners, check whether the power cord of it is connected to ensure that the ground wire is not damaged to prevent the leakage accident, prevent the power cord from good, avoid entanglement, prevent personnel from preventing personnel from being prevents personnel from being entangled, and prevent personnel from preventing personnel.

Check whether the nuts, bolts, etc. of all fixtures of the welding positioners are tightened, and check whether each axis is loose and tighten; check whether the reducer and the driver device are running normally.

3. The turntable can fix a dedicated welding chuck or other tools on the workbench to clamp the workpiece (pipe flange)for manual welding. The welding positioners can also be used with welding operators to achieve automatic welding and is widely used in the process of welding, cutting, polishing, assembly, painting, and detection.

4. Operate according to your own carrying capacity. The model of the welding turning table is different, and its carrying capacity is also different. Users need to choose the appropriate welding variable position according to their own workpiece specifications, which is conducive to ensuring the stability of the rotation.