Basic Info.

Usage

Transportation Chain

Transport Package

Wooden Cases

Specification

ISO, DIN

Trademark

JUXIN

Origin

China

HS Code

8431390000

Production Capacity

500PCS/Month

Product Description

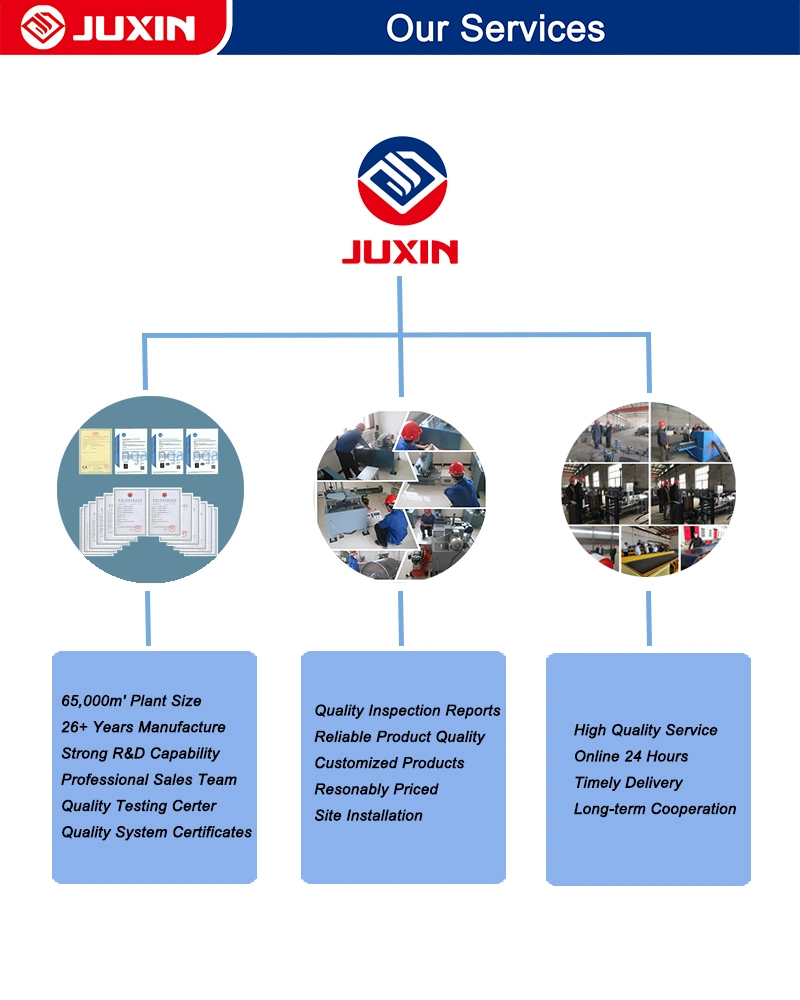

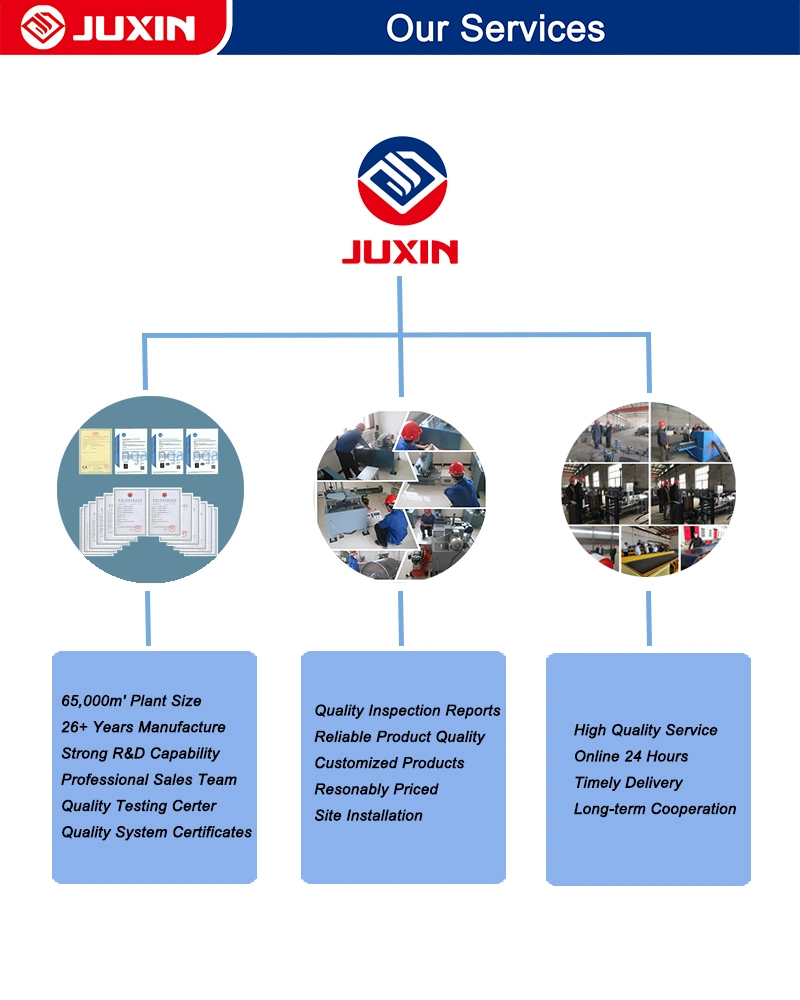

Established in 1976 in China, JUXIN, are considered as the first Conveyor and components: roller, frame, pulley manufacturer in Hengshui, China. The rapid growth of the business in China soon created the need for a distribution depot, therefore in 2007 a new branch was put in place in Tianjin City

The modern day JUXIN now manufactures conveyor products to suit all supplies of mining, steel plant, cement plant, quarry, crushing and screening equipment. Our expertise and knowledge allows us to deliver fully on our promises of providing quick answers to your enquiries, rapid service, high quality products and above all, we are fully committed to be the best at what we do.

Service Agents are also located in: UK, South Africa, Kenya, Indonesia, Thailand, Kazakhstan

JUXIN'S Pulleys are engineered to offer an efficient and improved alternative to standard stock Drum Pulleys. These pulleys simplify the selection as they can be used in a wide range of applications from standard, mine and quarry duty, thus reducing your replacement inventory. Submerged arc welding with machined-in weld preparation for maximum penetration, and are stocked with XT bushings but are also available for Keyless Locking Devices.

The modern day JUXIN now manufactures conveyor products to suit all supplies of mining, steel plant, cement plant, quarry, crushing and screening equipment. Our expertise and knowledge allows us to deliver fully on our promises of providing quick answers to your enquiries, rapid service, high quality products and above all, we are fully committed to be the best at what we do.

Service Agents are also located in: UK, South Africa, Kenya, Indonesia, Thailand, Kazakhstan

JUXIN'S Pulleys are engineered to offer an efficient and improved alternative to standard stock Drum Pulleys. These pulleys simplify the selection as they can be used in a wide range of applications from standard, mine and quarry duty, thus reducing your replacement inventory. Submerged arc welding with machined-in weld preparation for maximum penetration, and are stocked with XT bushings but are also available for Keyless Locking Devices.

| Welding | Full penetration weld using a high-strength submerged arc process |

| Machining | CNC Machining of end-discs and Shafts |

| Testing | NDT Testing is available |

| Stress Relieving | Thermal Stress Relieving ensures each component in the pulley operates as a pulley system |

| Balancing | Static Balancing is standard and dynamic balancing is available |