Basic Info.

Model NO.

ZFH-500

Effective Welding Length

500mm

Compression Method

Key Press Compression

Welding Thickness

0.5-6mm

Suitable Welding Wire Diameter

1.0/1.2/1.4/1.6mm

Control Mode

Optional PLC or Relay Integrated Control

Arc Welding Power Source

TIG Welding/CO2 Welding/Plasma Arc Welding

Current

AC

Input Voltage

380V-440V

Load Duration

100%

Lead Time

20 Days

Dimensions

Customized

Colour

Customized

Transport Package

Wooden

Trademark

Lemar

Origin

Wuxi, China

HS Code

8515390000

Production Capacity

500 PCS/Year

Product Description

There are two types of Metal pipe vessel straight seam welding machines:

General-purpose straight seam welding machines and special straight seam welding machines.

The general-purpose straight seam welding machines are mainly divided into seven types:

ZFH-500/1000/1200/1300/1500/2000/2500.

The straight seam welding machine is mainly a customized product. Special fixtures can be designed and manufactured according to customer needs, which are specially designed for the welding of the same or the same type of workpiece.

Stainless steel carbon steel tank seam welders are suitable for welding processes such as TIG (GTAW), MIG (GMAW), plasma (PAW) and sub arc welding (SAW).

Applicable industries:

High pressure solar water heater tank

Low pressure solar water heater tank

Electric water heater enamel water tank

ZFH cylinder

ZFH filling station

Storage tank

Stainless steel carbon steel tank seam welders are suitable for welding processes such as TIG (GTAW), MIG (GMAW), plasma (PAW) and sub arc welding (SAW).

Applicable industries:

High pressure solar water heater tank

Low pressure solar water heater tank

Electric water heater enamel water tank

ZFH cylinder

ZFH filling station

Storage tank

Parameters:

| Model | ZFH-500 |

| Effective welding length | 500mm |

| Walking accuracy | ±0.1mm |

| Welding thickness | 0.5-6mm |

| Welding process | TIG/MIG/Paw/Mag Welding |

| Welding Material | steel,cast iron,stainless steel ,aluminum or cooper |

| HS Code | 8515390000 |

| Suitable welding wire diameter | 1.0/1.2/1.4/1.6mm |

| Welding power source | Miller or lincoln or fronius or Japan OTC or panasonic or China Aotai |

| Welding torch lifting range | 100mm |

| Welding torch moving range in left-right direction | 100mm |

| Machine working voltage | 380v 3phase 50hz |

| Welding speed | MIG Welding speed:about 500mm/min TIG Welding speed:300mm/min Plasma welding :about 500mm/min |

| Control system | Japan Omron PLC and touch screen |

Main feature :

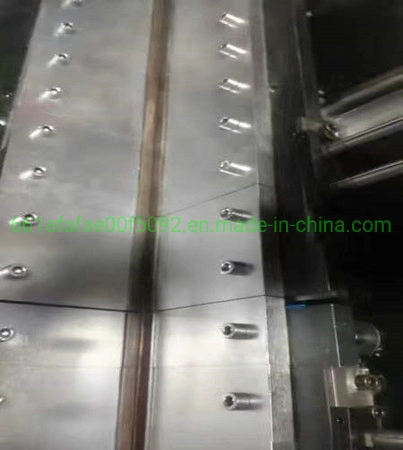

1. The welding host of the ZFH Cylinder seam welding machine adopts a cantilever structure to ensure that the beam will not be deformed for a long time

2.The pneumatic pressing structure is closely arranged along both sides of the straight seam to ensure that the butt welding seam is evenly pressed in the entire welding length

3.The welding mandrel of the cylindrical straight seam welding machine of the solar water heater is inlaid with a copper water-cooling circulation system mold; it provides the protection function of the back air of the welding seam.

4.The distance between the welding mandrel and the pressure plate finger is adjustable, which can adapt to the welding requirements of workpieces with different thicknesses

5.According to the cylinder or flat workpiece, different welding process grooves are processed to achieve single-sided welding and double-sided forming

1. The welding host of the ZFH Cylinder seam welding machine adopts a cantilever structure to ensure that the beam will not be deformed for a long time

2.The pneumatic pressing structure is closely arranged along both sides of the straight seam to ensure that the butt welding seam is evenly pressed in the entire welding length

3.The welding mandrel of the cylindrical straight seam welding machine of the solar water heater is inlaid with a copper water-cooling circulation system mold; it provides the protection function of the back air of the welding seam.

4.The distance between the welding mandrel and the pressure plate finger is adjustable, which can adapt to the welding requirements of workpieces with different thicknesses

5.According to the cylinder or flat workpiece, different welding process grooves are processed to achieve single-sided welding and double-sided forming

6.The welding torch of longitudinal seam welding is driven by DC motor. Inner steel wire belt drive, Taiwan precision track, stable running, stable and reliable welding.

7.All trachea and cables are placed in the drag chain, the appearance is neat and beautiful, and the cable breakage is avoided at the same time.

8. Excellent weld quality and high degree of automation.

7.All trachea and cables are placed in the drag chain, the appearance is neat and beautiful, and the cable breakage is avoided at the same time.

8. Excellent weld quality and high degree of automation.

Lemar has many years of experience specializing in mechatronics products such as cutting and welding equipment, CNC machinery, robot auxiliary equipment, etc.; has cultivated a team of experienced and highly skilled talents

Our main products are:

Box beam production line series

H-beam production line series equipment

U-beam production line series equipment

Wind tower production line

CNC cutting series

Shot blasting machine

Automatic welding center

Automatic welding manipulator

Welding roller rotator

Welding positioner

Longitudinal seam welding machine

Circumferential seam welding machine

etc.

The products cover all parts of the country and are exported to Europe, America, Southeast Asia and the Middle East and other countries. It is one of the domestic H-beam production line export bases.

Economic globalization has brought unprecedented development opportunities to Lemar Machinery.

In the wave of economic globalization, we will build a world-class brand and move towards a higher goal!