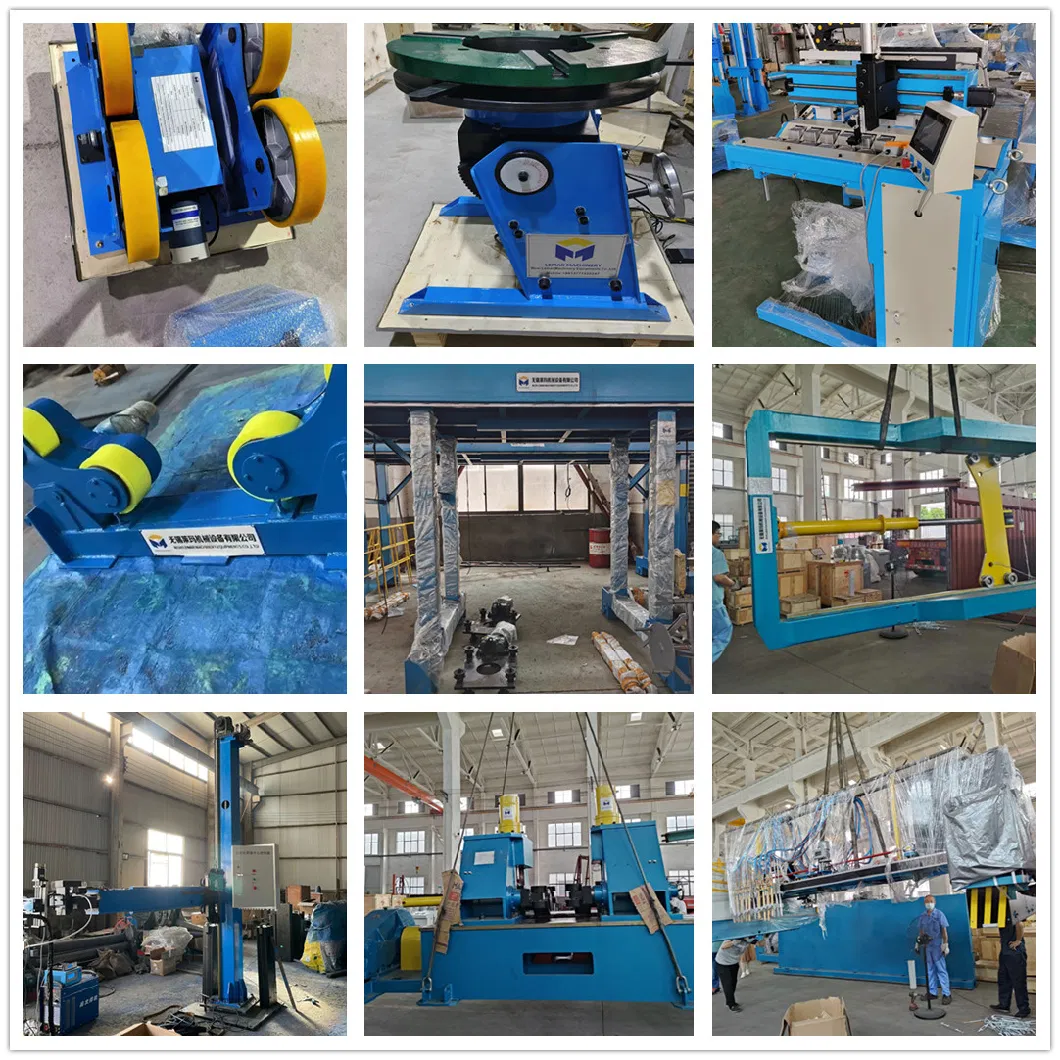

- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Product Usage

- Product Advantage

- Our Main Products

- Packaging & Shipping

Basic Info.

Packaging & Delivery

Product Description

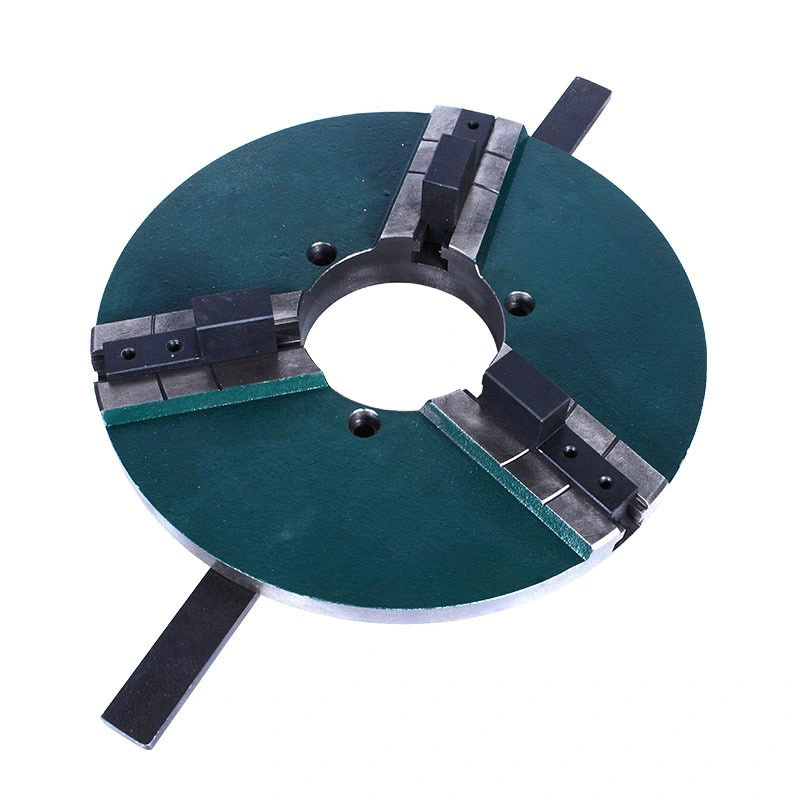

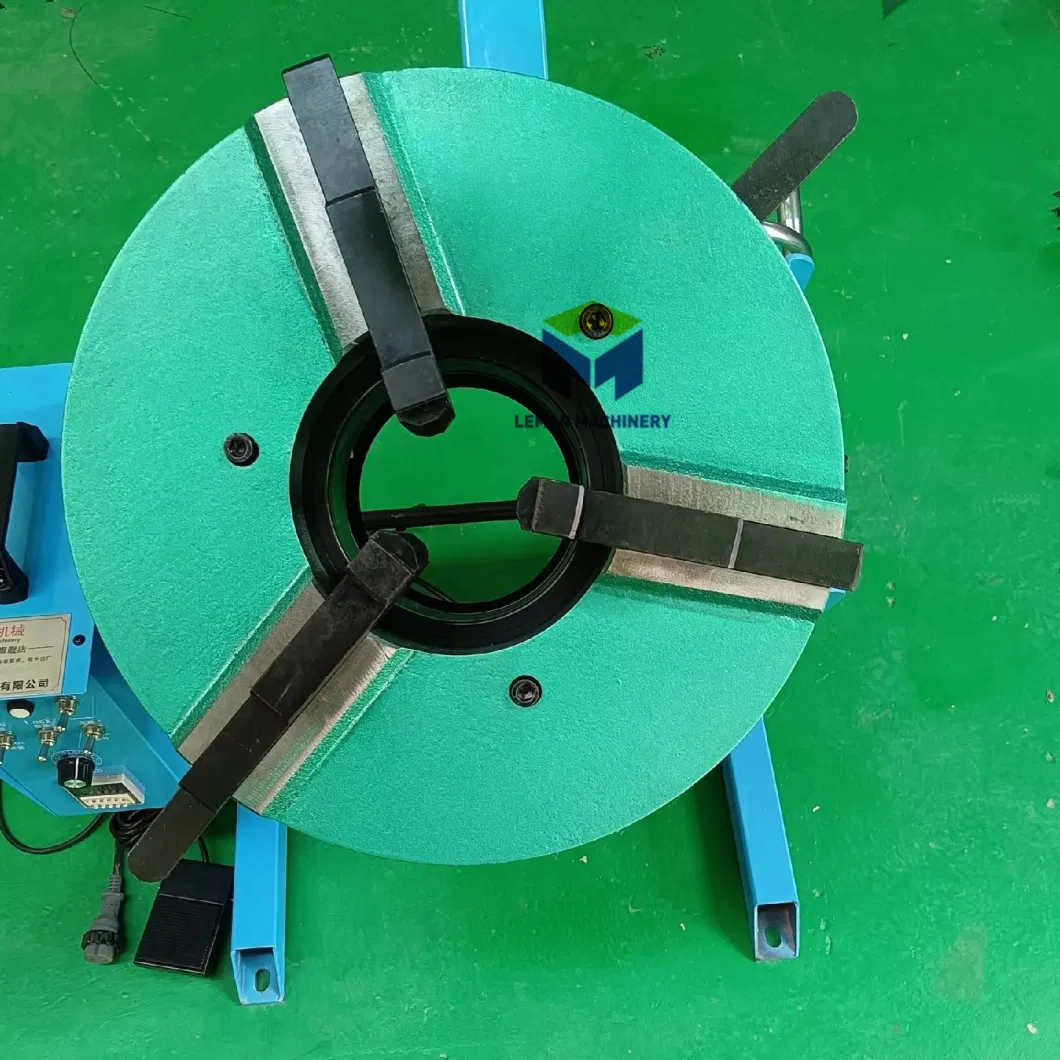

Welding Chuck for Welding positioner turning turntable

The quick chuck with handle is specially designed for the welding positioner, it is specially used to withstand the fixture of the welding industry, the self-centering three-jaw industrial chuck can clamp and loosen the workpiece quickly and accurately, they are mainly used for fixing on Customized metal parts on headstock/tailstock for automatic welding with welding positioner, TIG welding machine, MIG welding machine, etc.Our jig welding chucks can also be adjusted for external or internal chuck welding.

Our welding chucks are designed for fast, self-centering applications. 3-jaw system allows quick positioning along the slide bar.

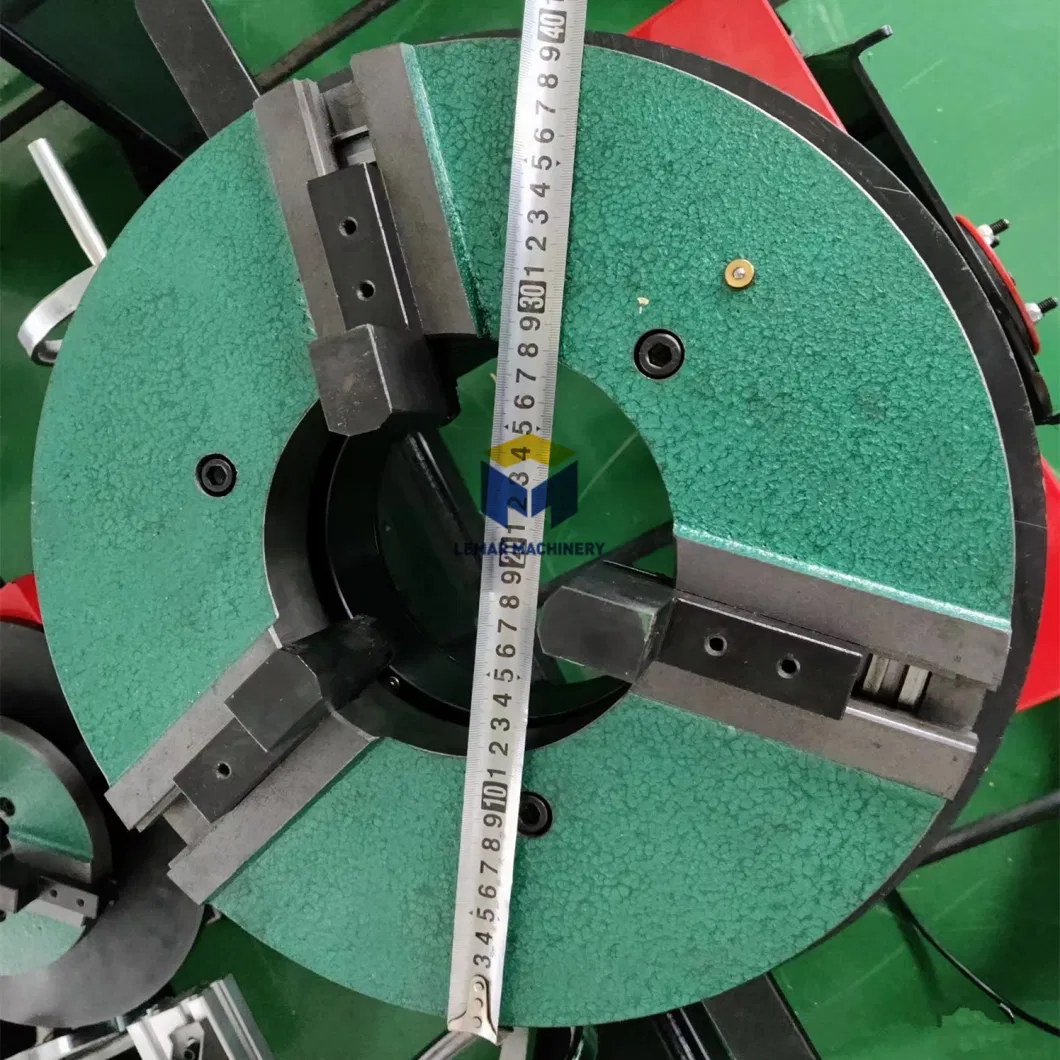

| Model | Required clamping force | Loading weight | Anti-grab clamping range A | Anti-grab clamping range B | Extended clamping range |

| KP200 | 200KG | 30KG | Ф110-210 | Ф20-130 | Ф5-300 |

| KP300 | 250KG | 120KG | Ф170-280 | Ф80-190 | Ф10-400 |

| KP400 | 350KG | 240KG | Ф250-380 | Ф120-250 | Ф10-500 |

| KP500 | 800KG | 600KG | Ф360-500 | Ф200-360 | Ф40-600 |

| KP600 | 1200KG | 1000KG | Ф450-600 | Ф300-450 | Ф40-750 |

The use of three-jaw chuck:

1. Install the self-centering three-jaw chuck on the machine tool, and select the machine tool (welding positioner) to use with the hollow shaft sleeve

2. By adjusting the height of the hollow bushing, the hollow bushing can make the three claws close to the table of the welding positioner

3. Place the workpiece (pipe, flange, elbow) on the claws, and tighten the fixing screws so that the three claws can firmly and accurately clamp the workpiece

4. After the above steps, the workpiece can be installed on the machine tool, especially the rotary welding turntables for stable processing

1. The three-jaw chuck has simple structure, low cost and easy operation

2. It can clamp the workpiece (pipe, elbow, flange, etc.), has a long working time, is not easy to slip, and has high positioning accuracy

3. It can be adjusted with the dial indicator to make the processing technology more accurate and work more efficient

4. It can clamp the workpiece, has great elasticity and has a floating function, which can better ensure the machining accuracy.